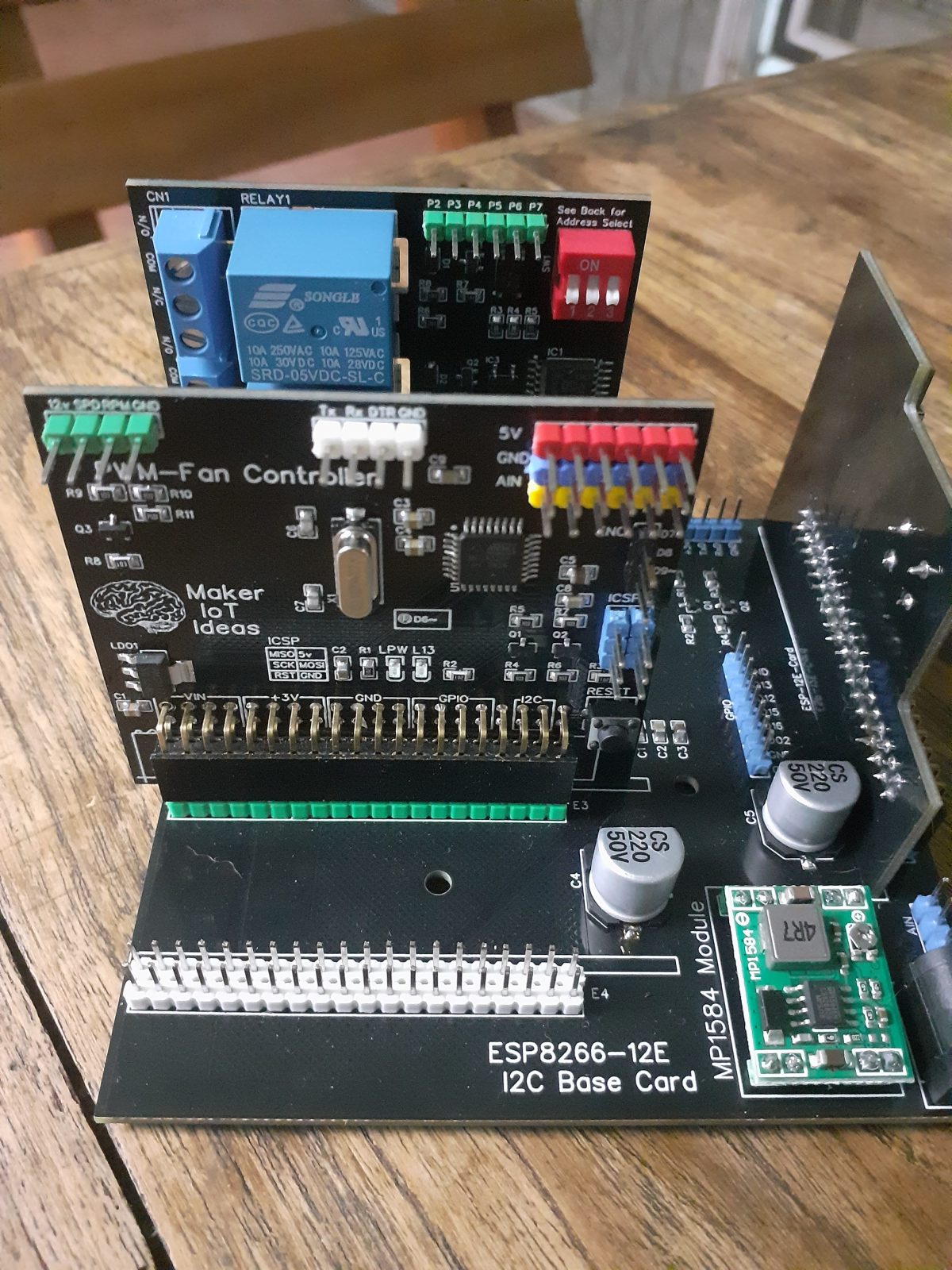

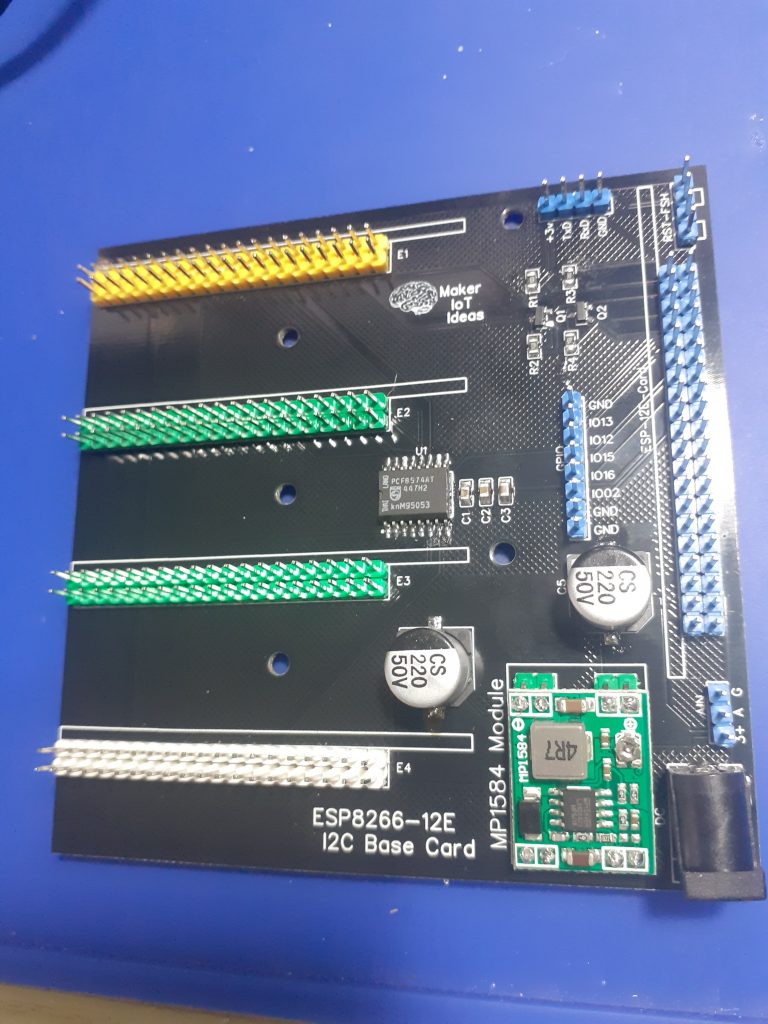

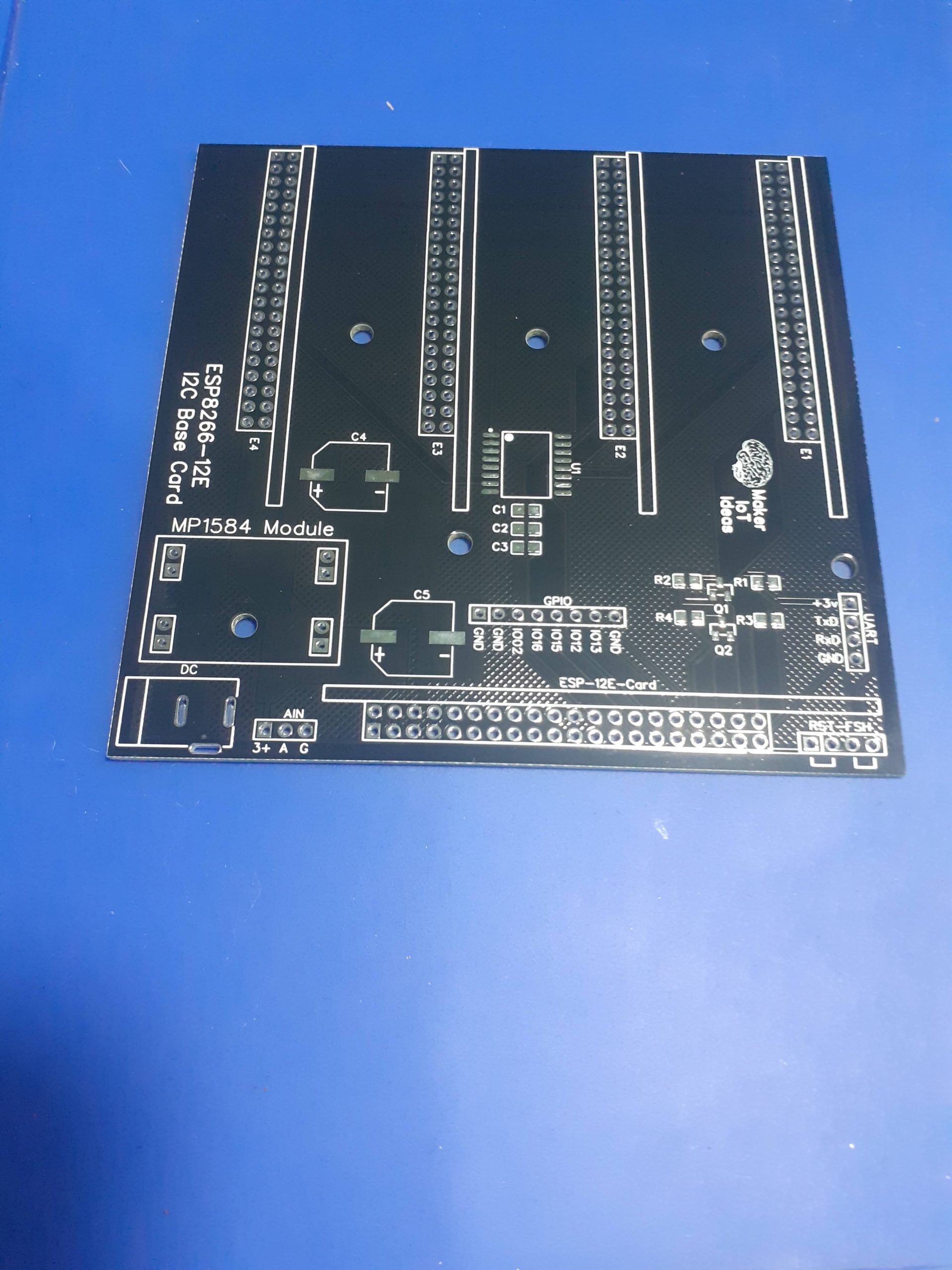

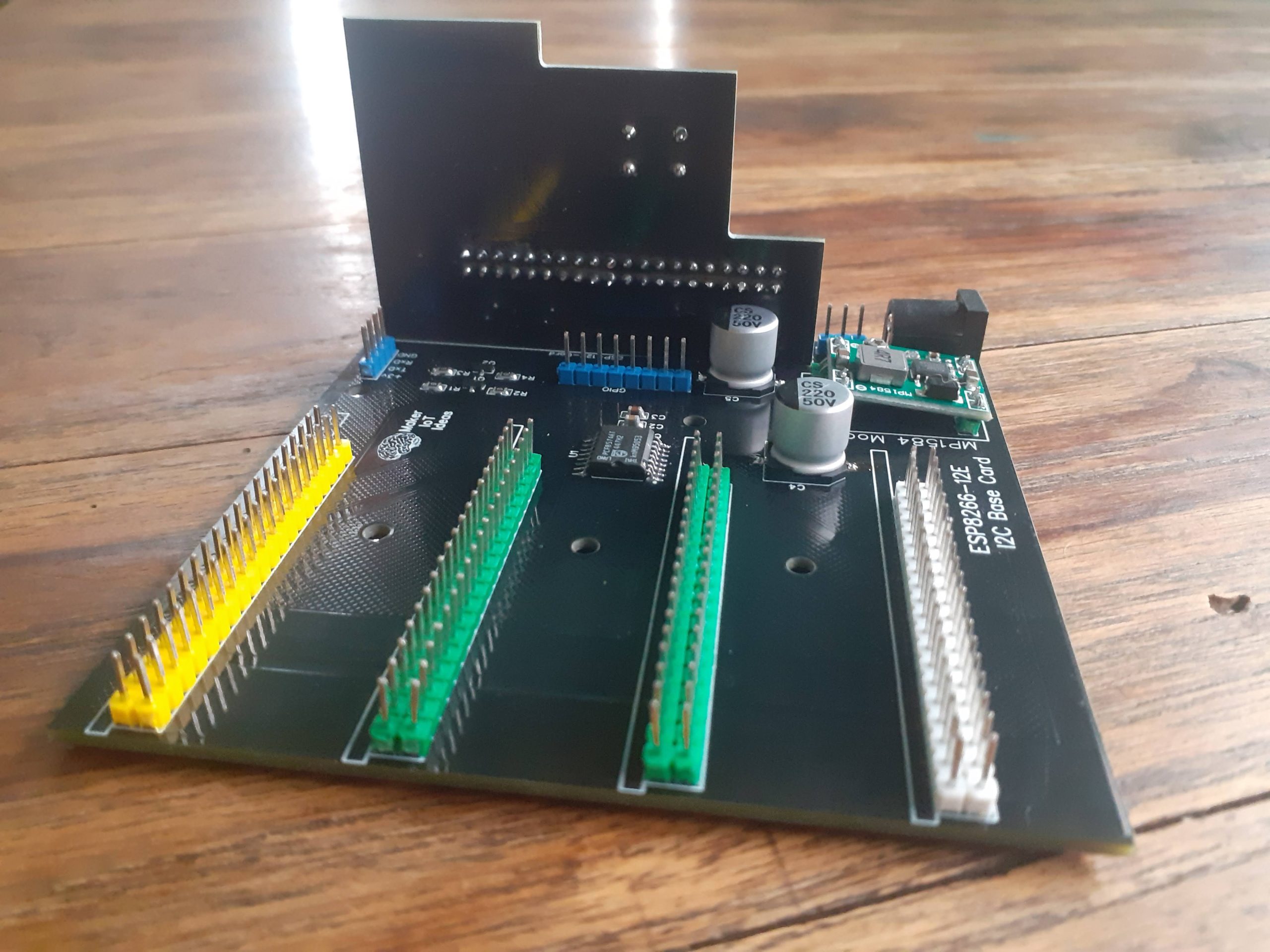

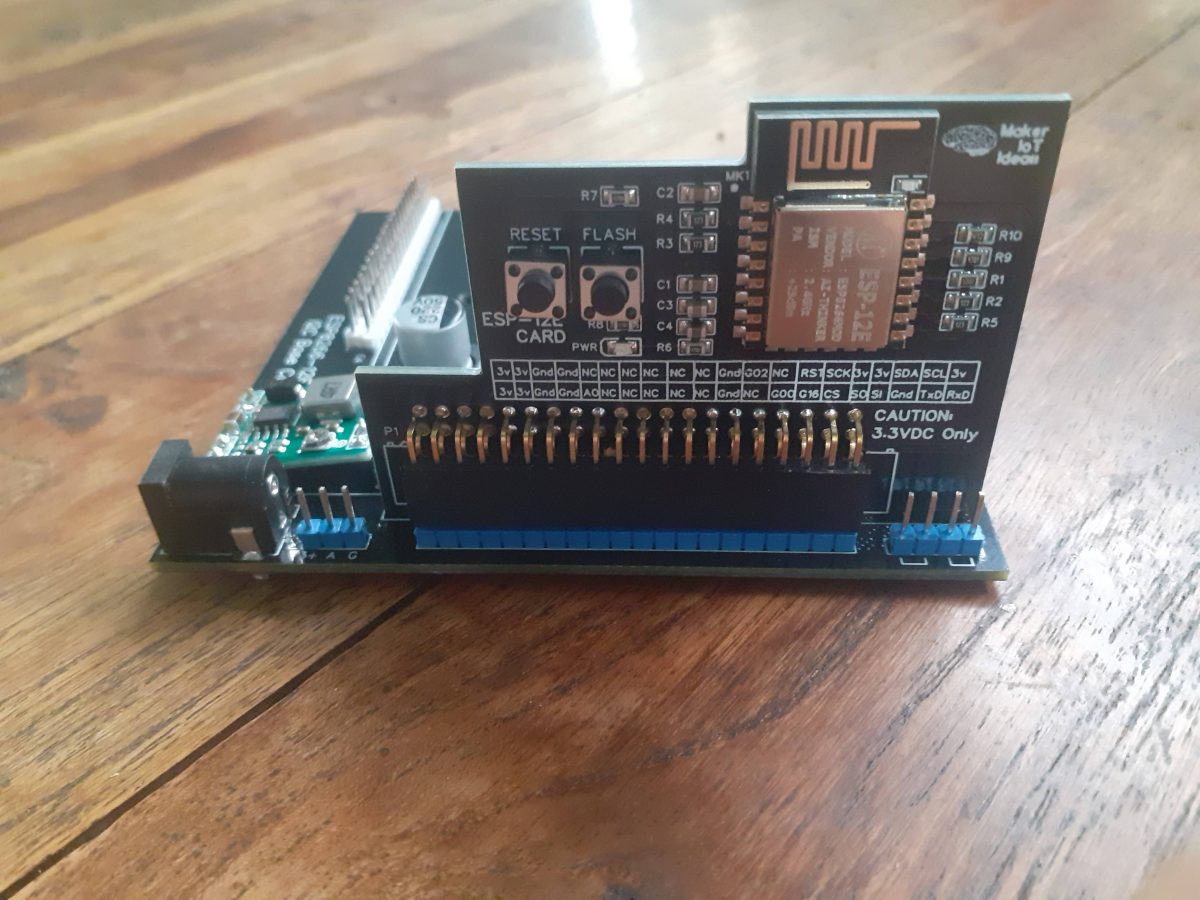

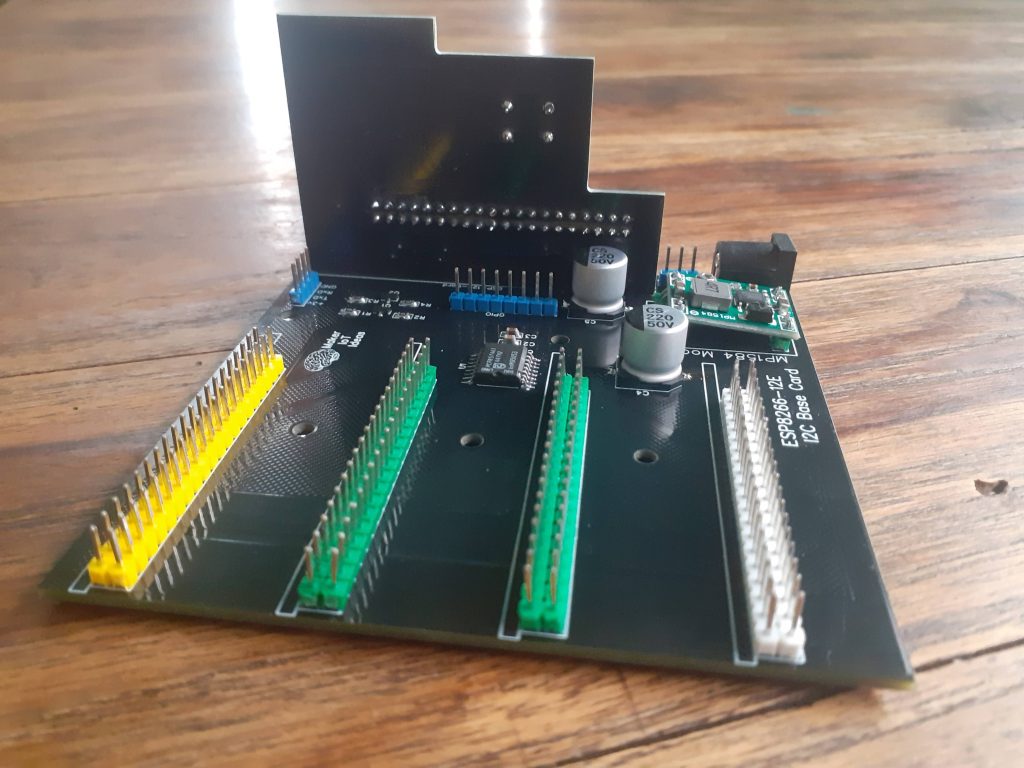

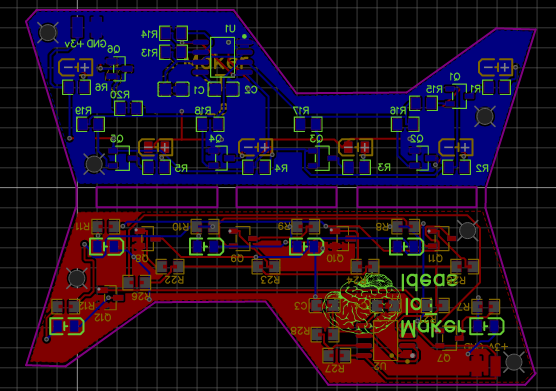

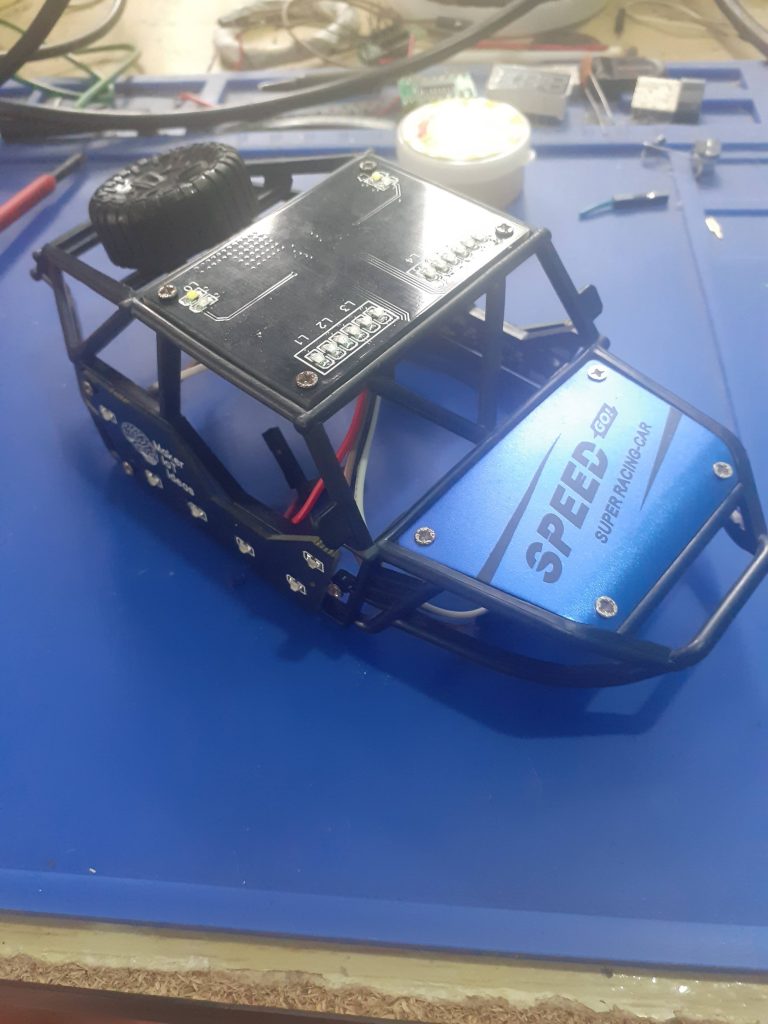

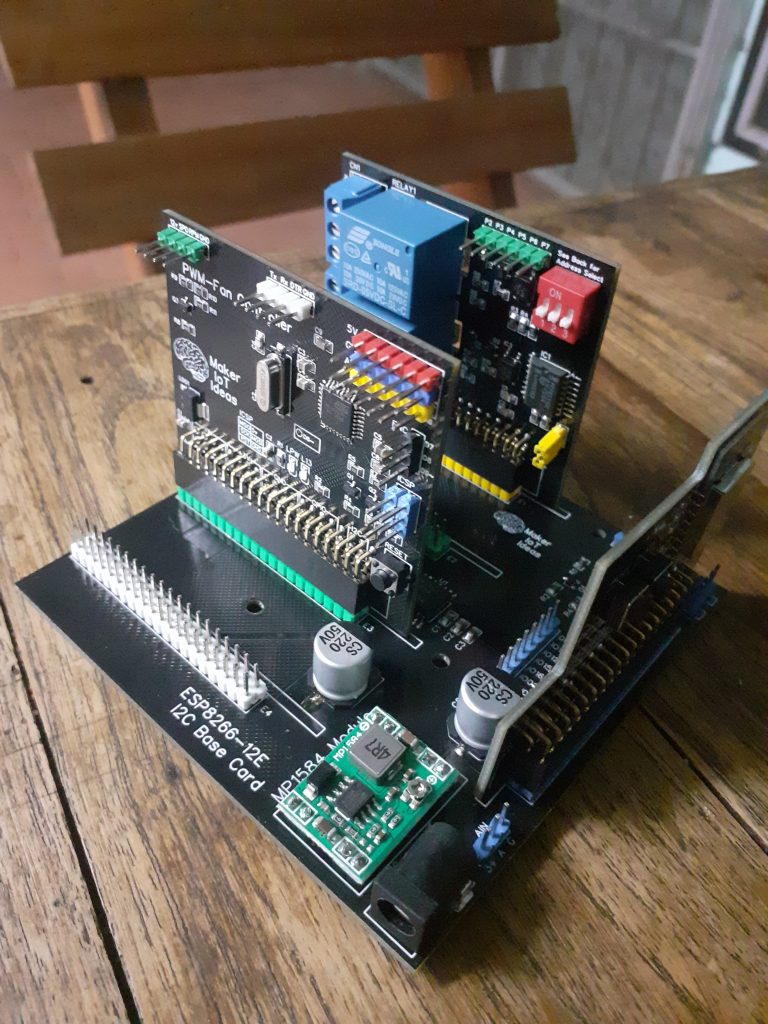

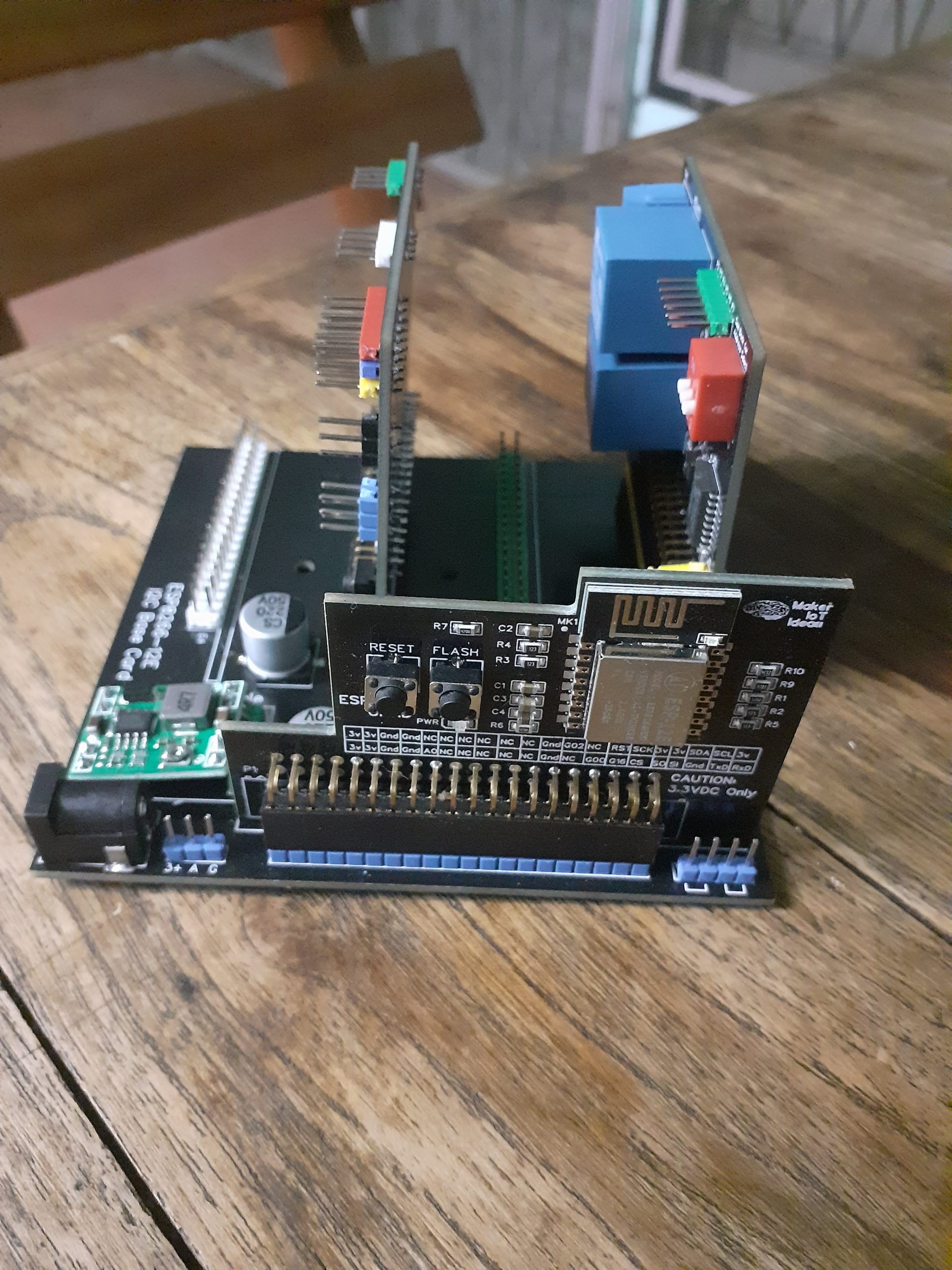

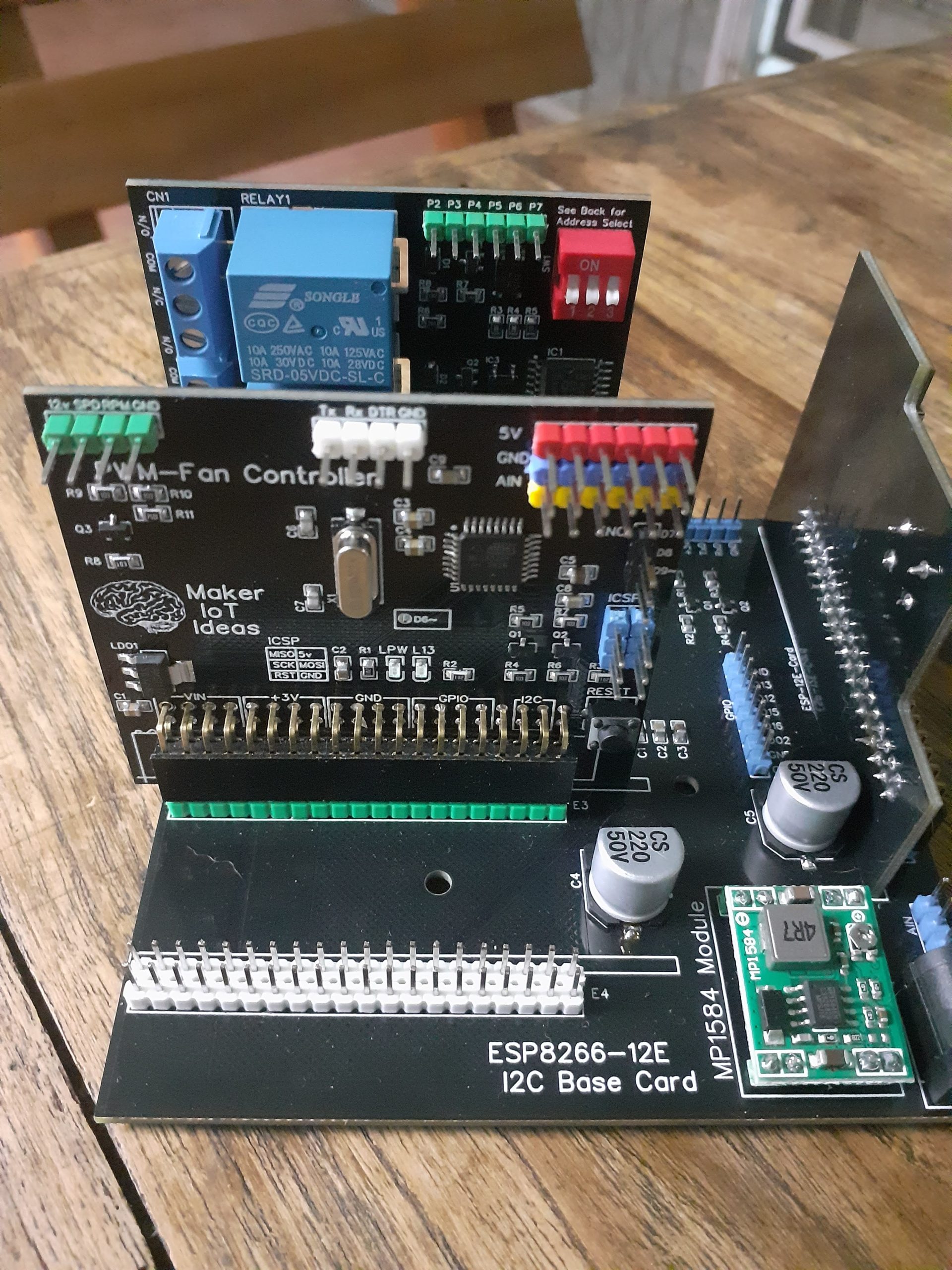

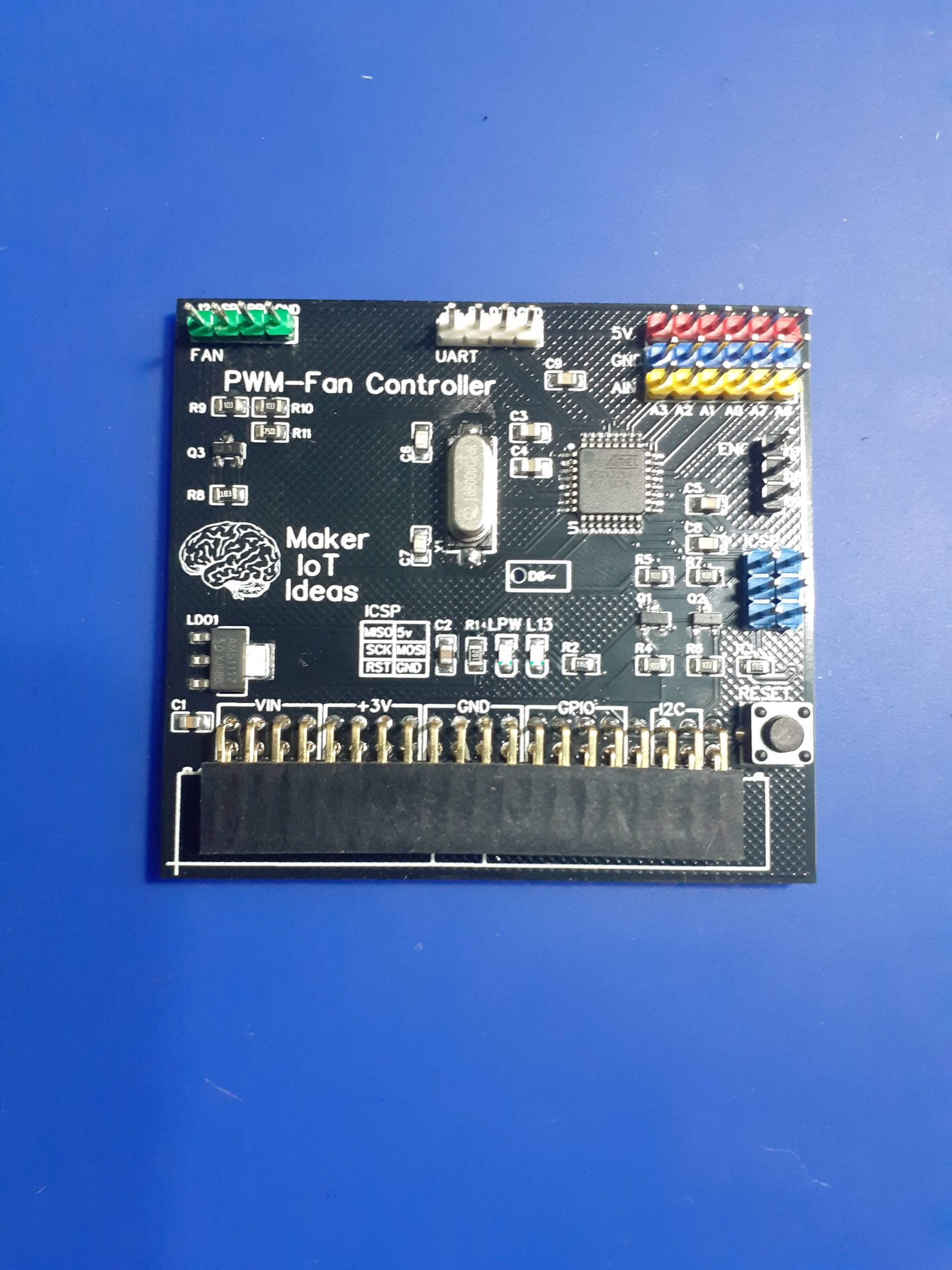

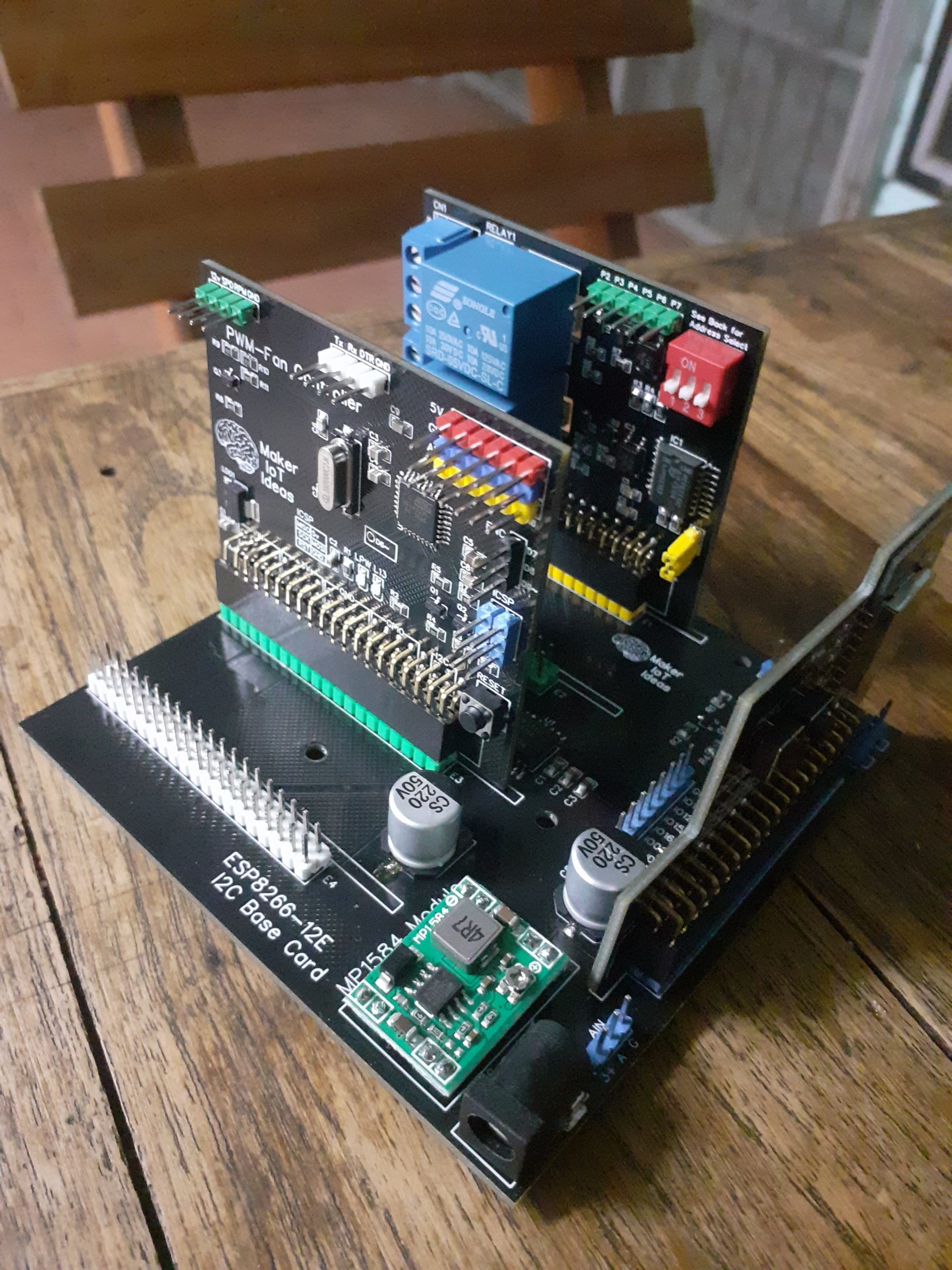

As part of my recent ESP-12E I2C Base Board project, I designed an ATMega 328P Based PWM controller card, that can be used as an add-on card with the existing project, or standalone as a custom Arduino Nano compatible development board.

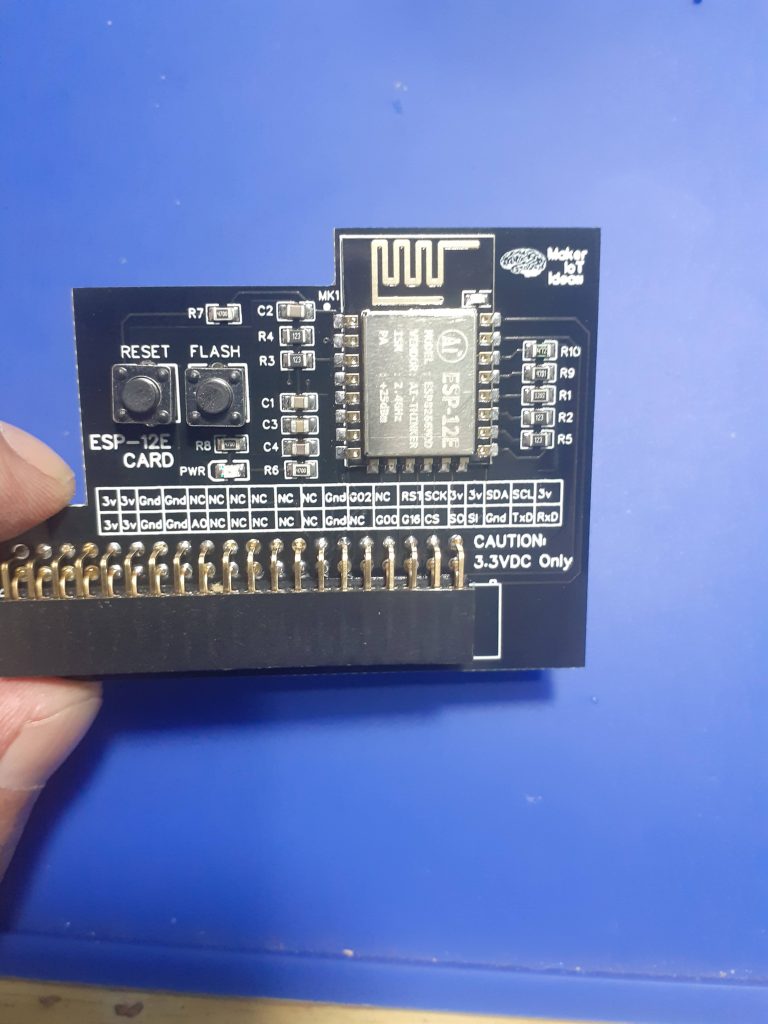

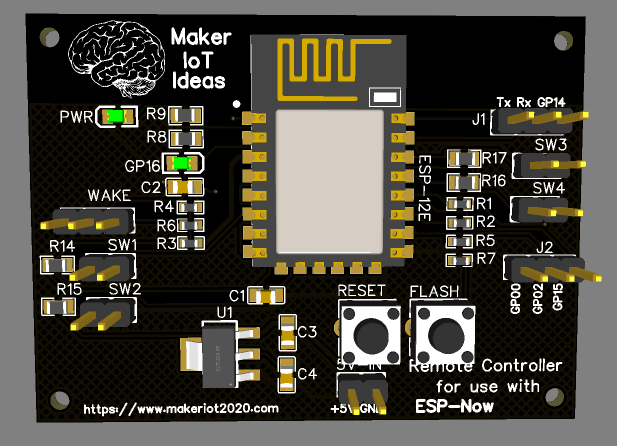

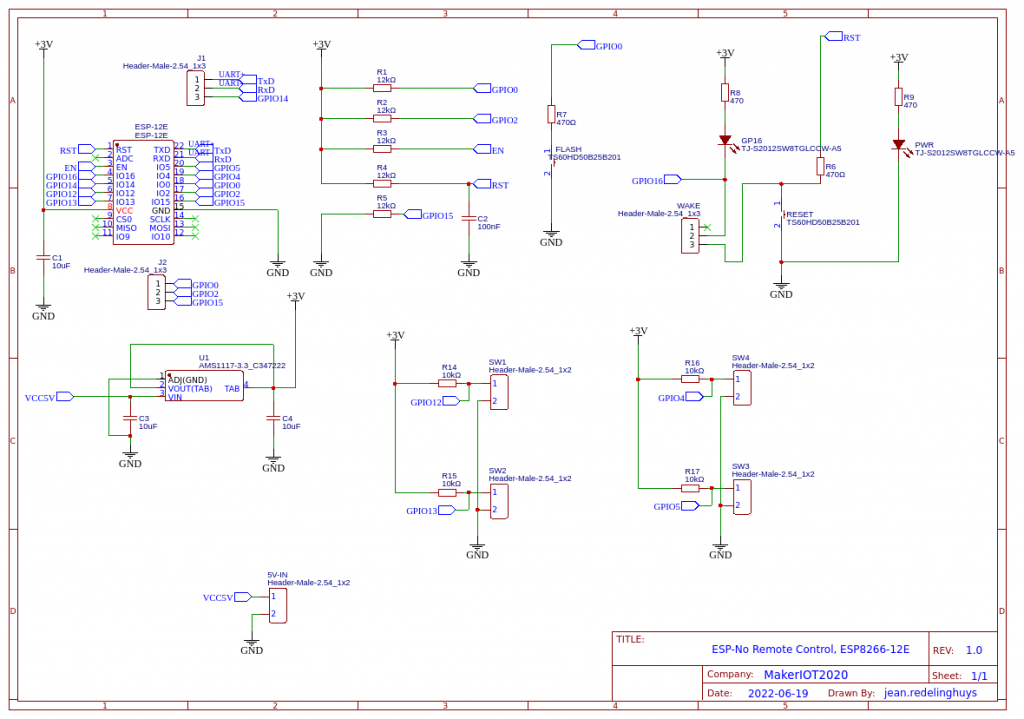

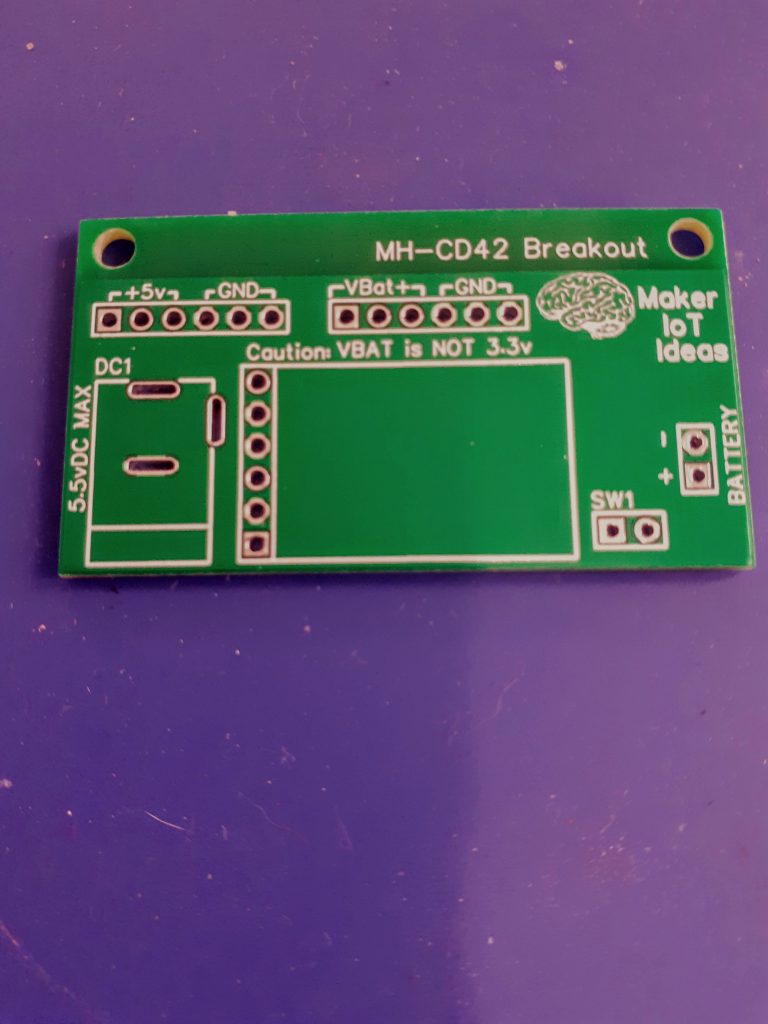

What is on the PCB?

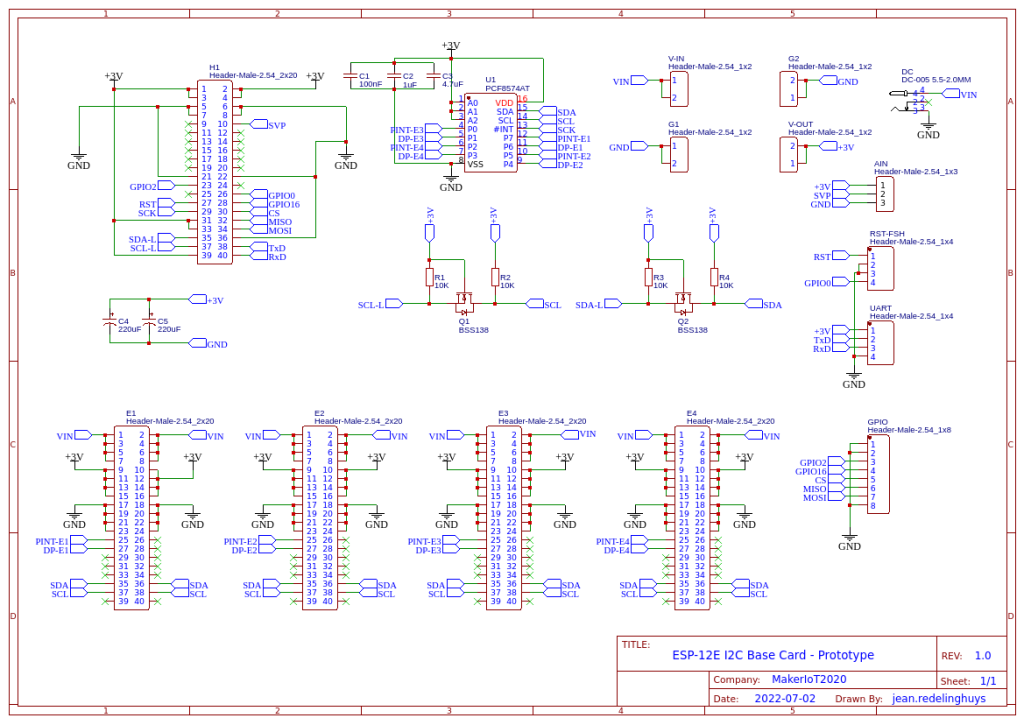

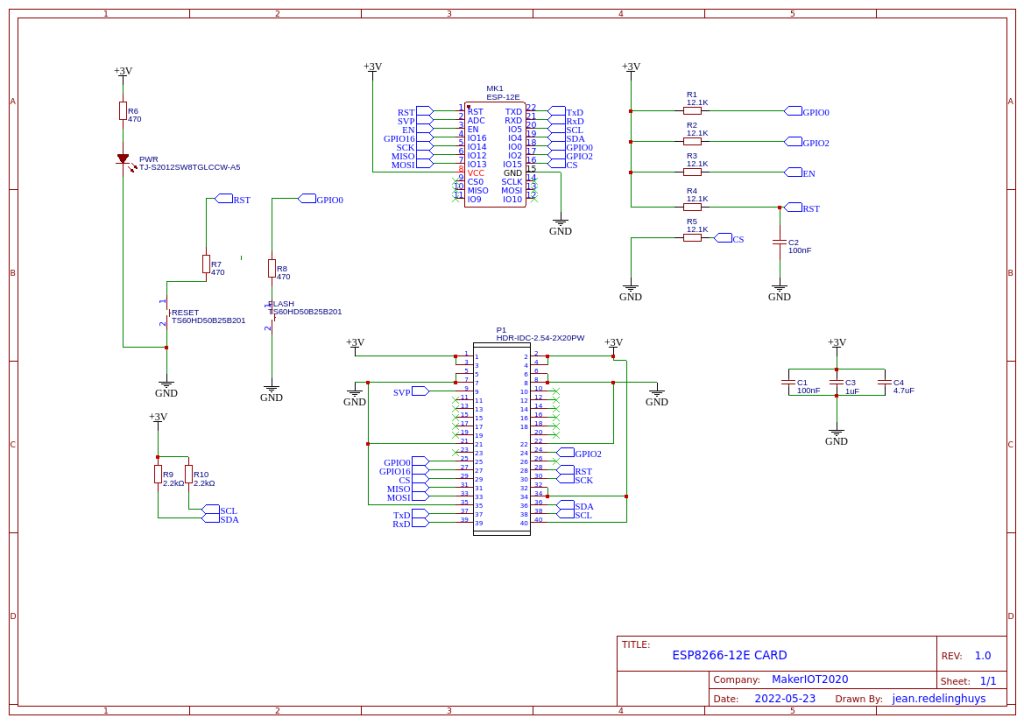

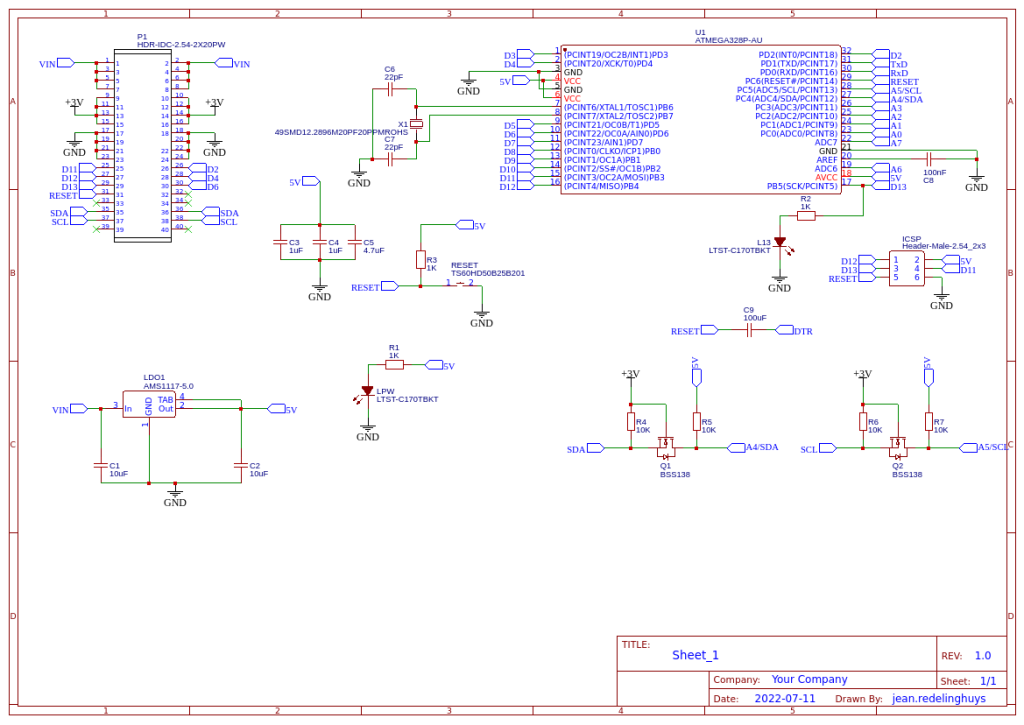

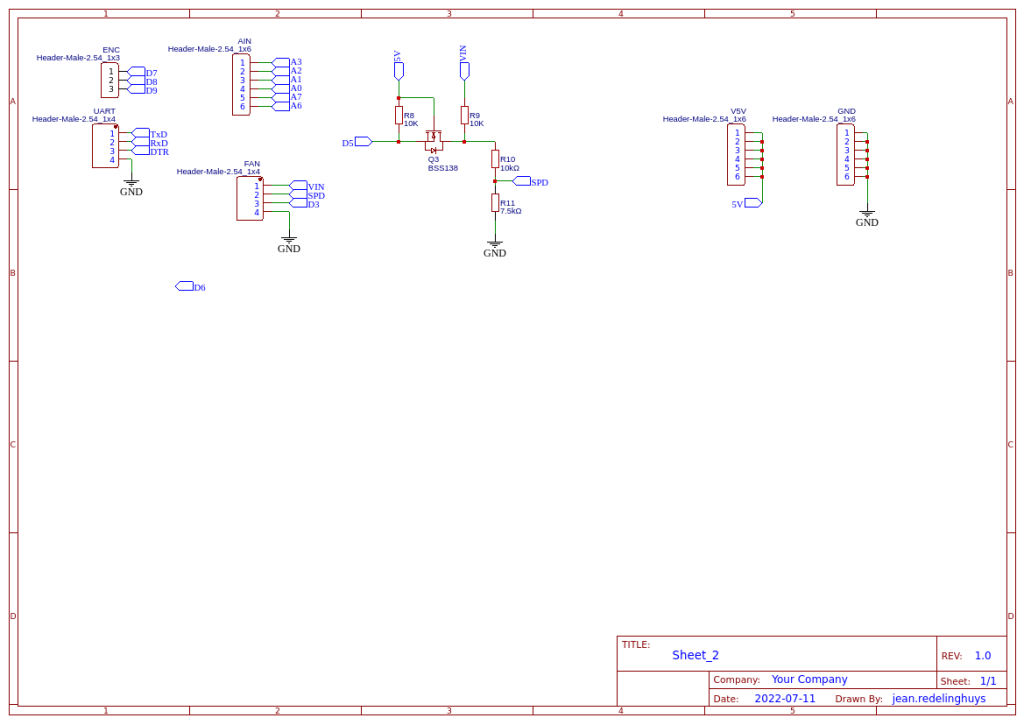

The PWM controller card contains standard Arduino Nano circuitry running at 16MHz, without the USB to Serial converter, as well as a 3v to 5v level converter on the I2C port ( A4 and A5 ), as well as another 12v to 5v level converter, with a build in resistor-divider circuit, used to drive a 12v blower with 3.3v PWM control circuitry.

All analog inputs are broken out to make attaching additional sensors easier.

All the other unused GPIO pins are also broken out, either directly to headers on the PCB (D6~,D7,D8,D9~), D11,D12,D12 (ISCP Header) and D3 ( Marked RPM on the Fan Header)

Most of these pins are also additionally broken out onto the 2x20p female header at the bottom of the card ( See schematic for more details)

The board is designed to be powered from 12v DC (via the VIN pins on the 2x20p header) which is internally regulated down to 5v via an LDO voltage regulator.

External 3.3v should also be supplied to the 2x20Pin header to enable the I2C level converters on the same header. I2C is not directly broken out onto the PCB in this version of the PCB.

A reset button, and power led, as well as the standard led on D13 is also provided.

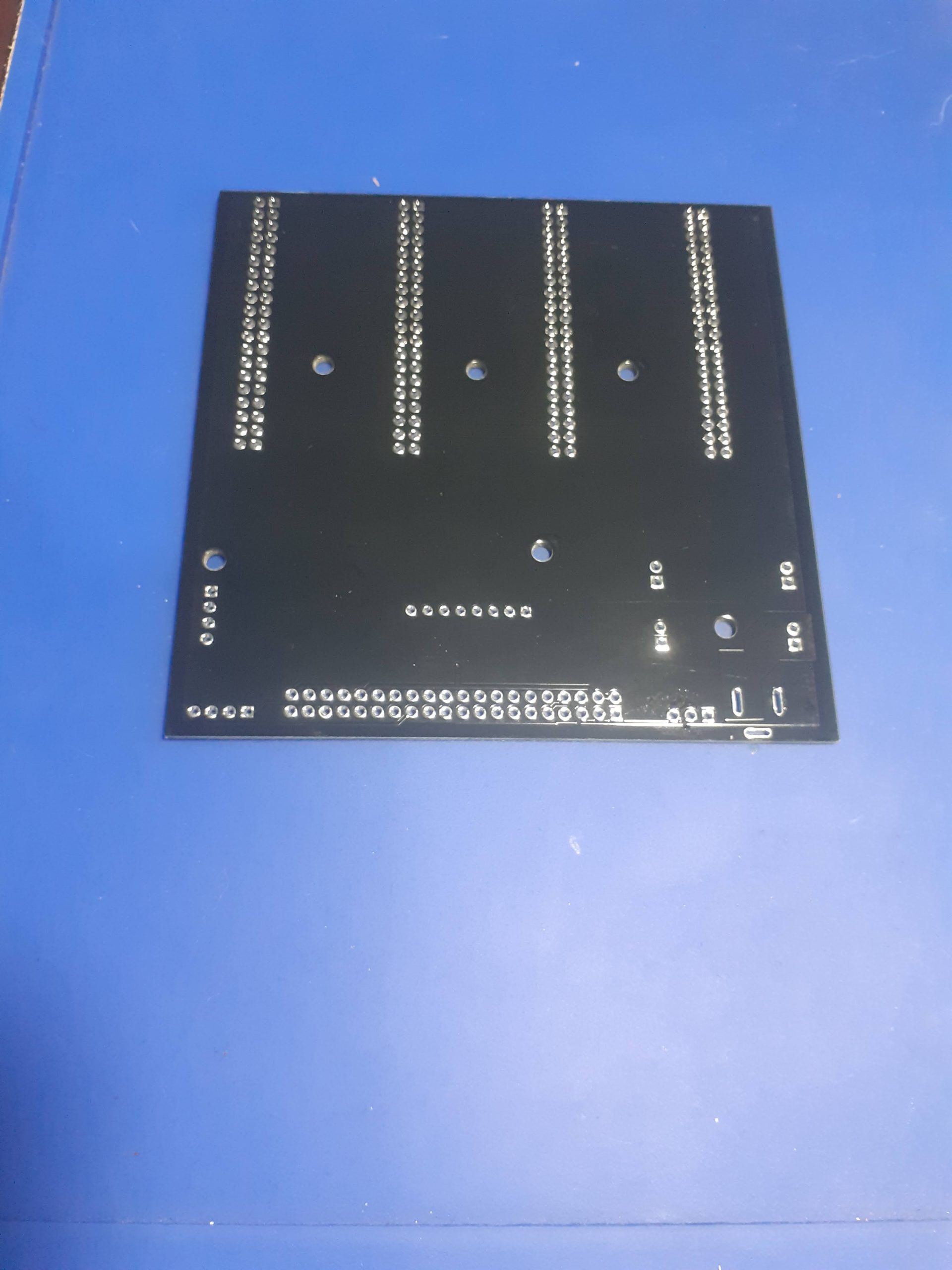

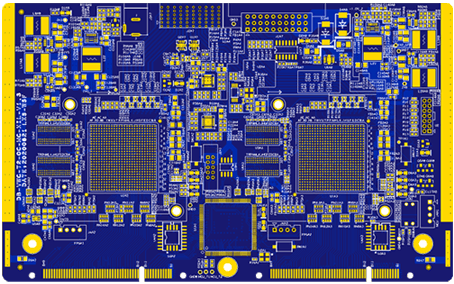

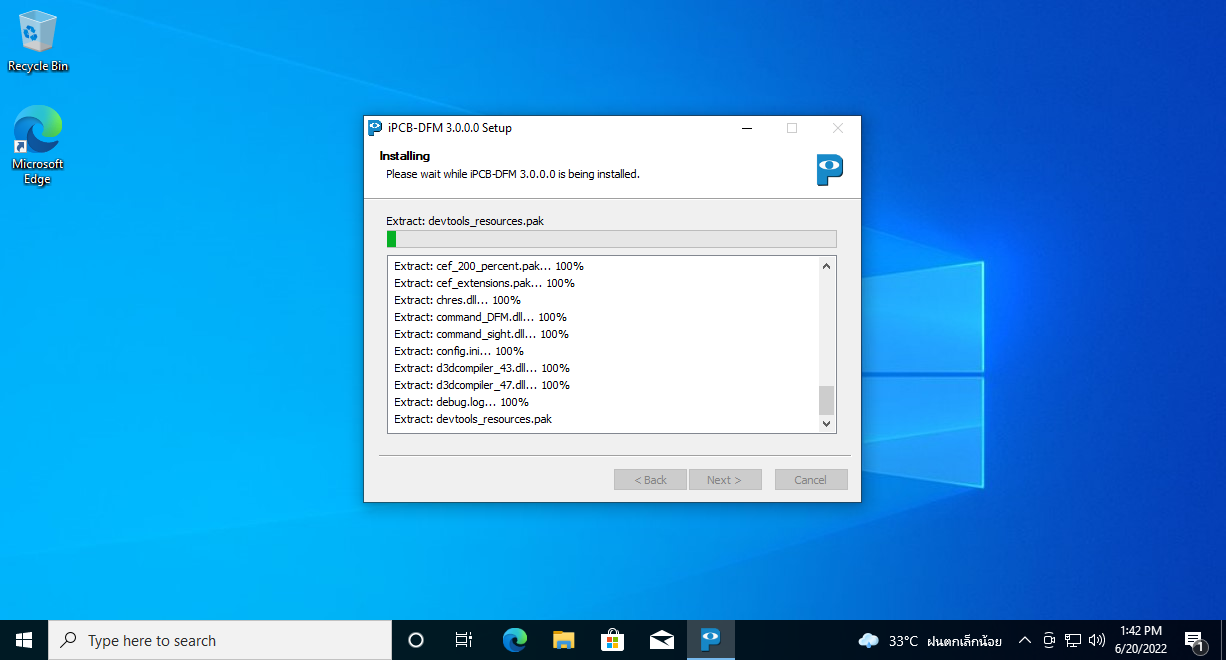

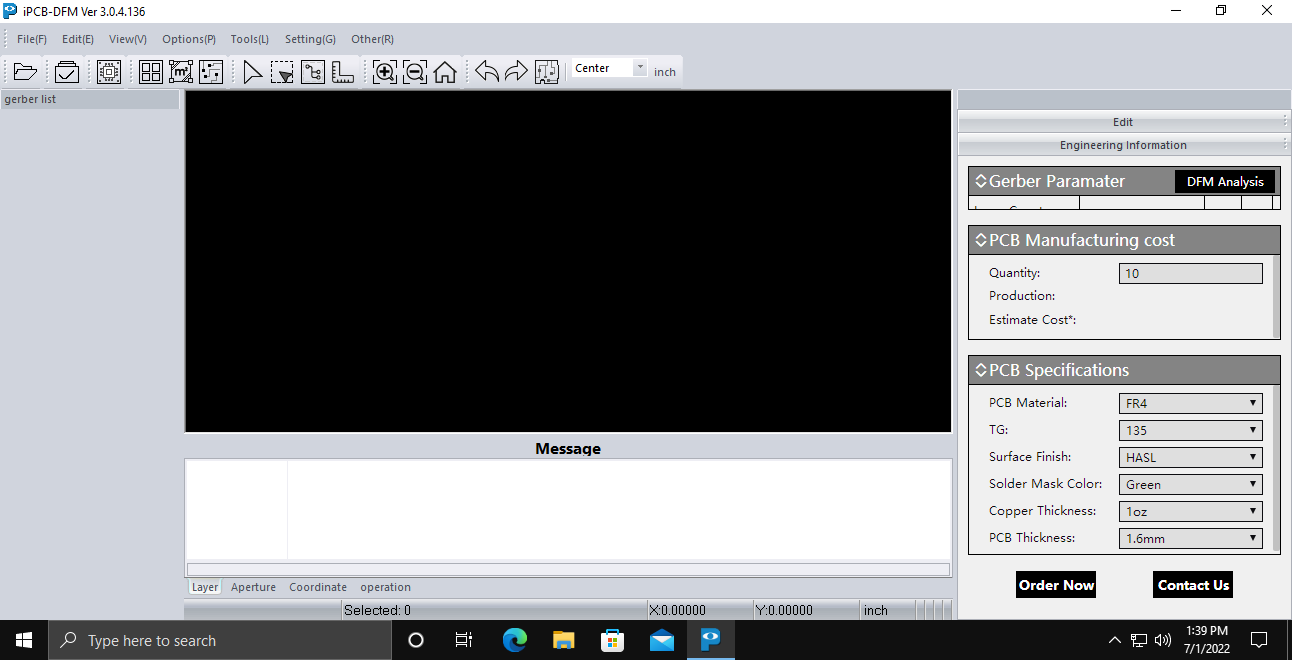

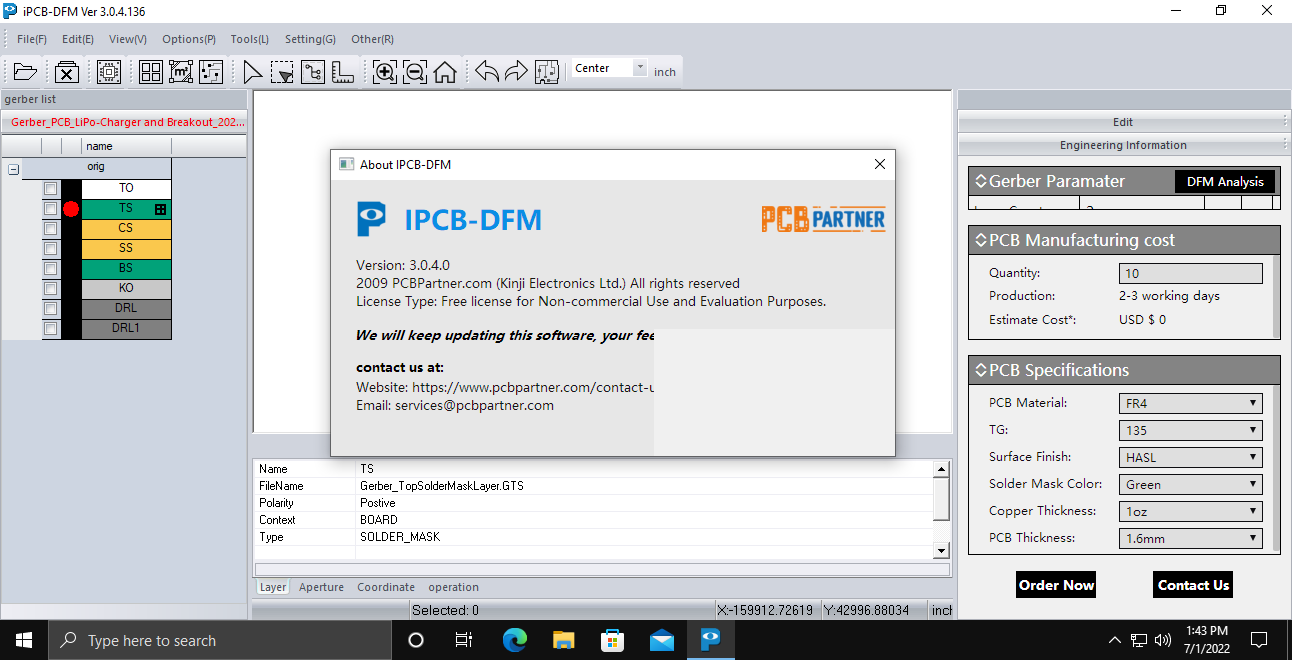

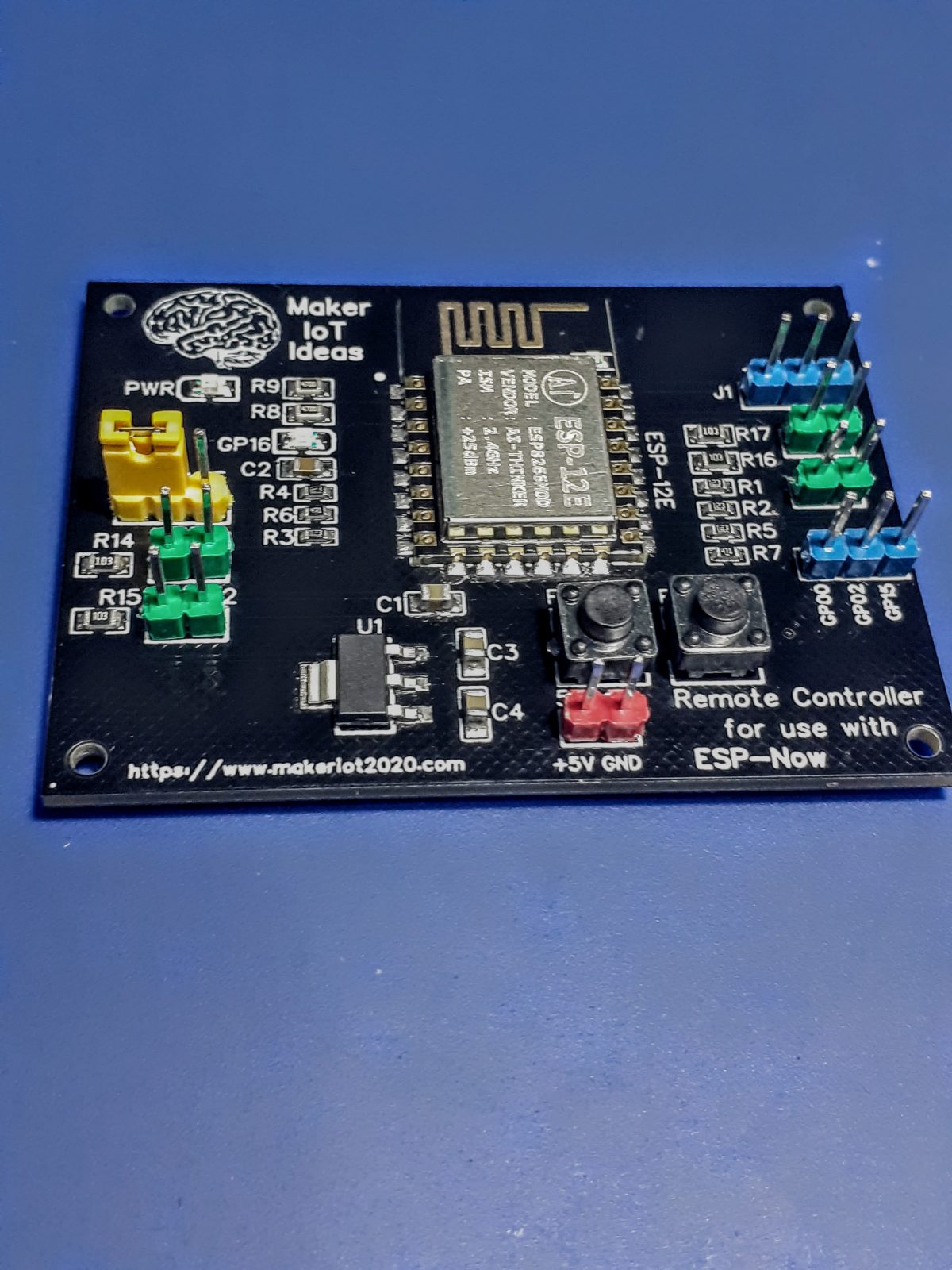

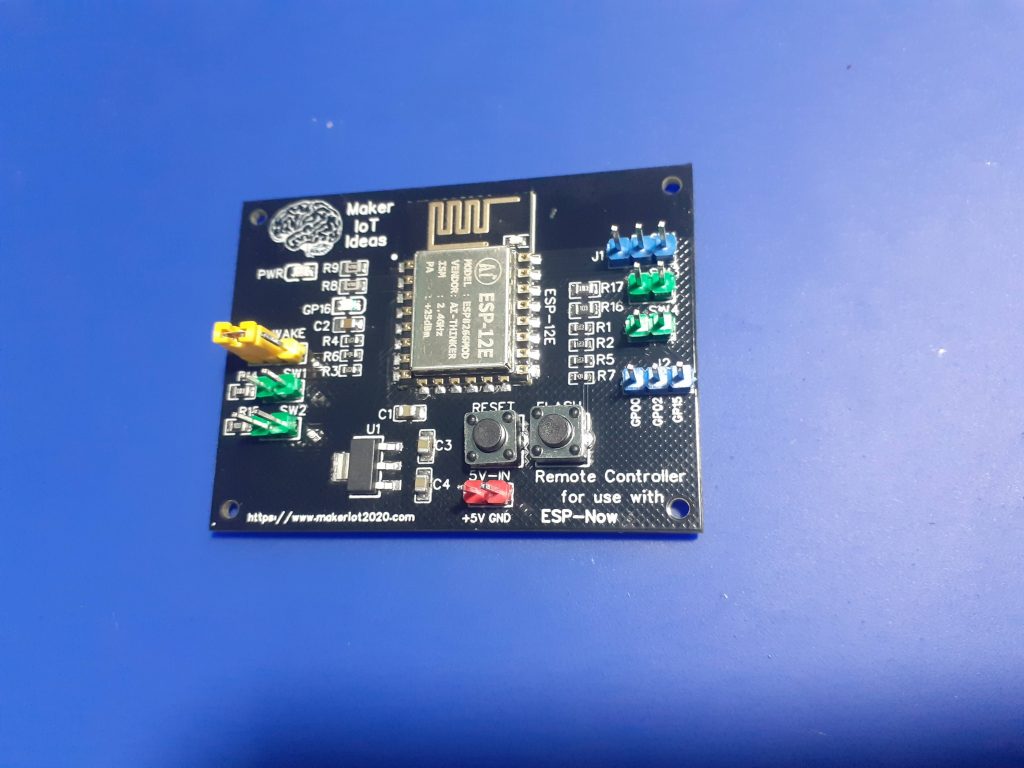

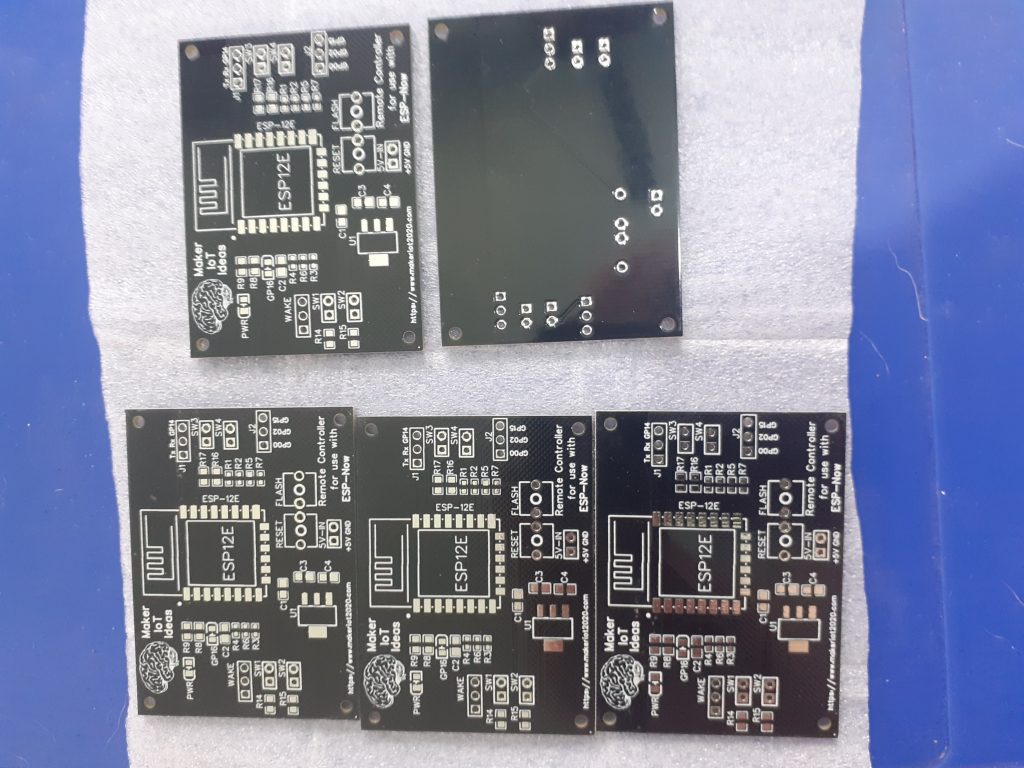

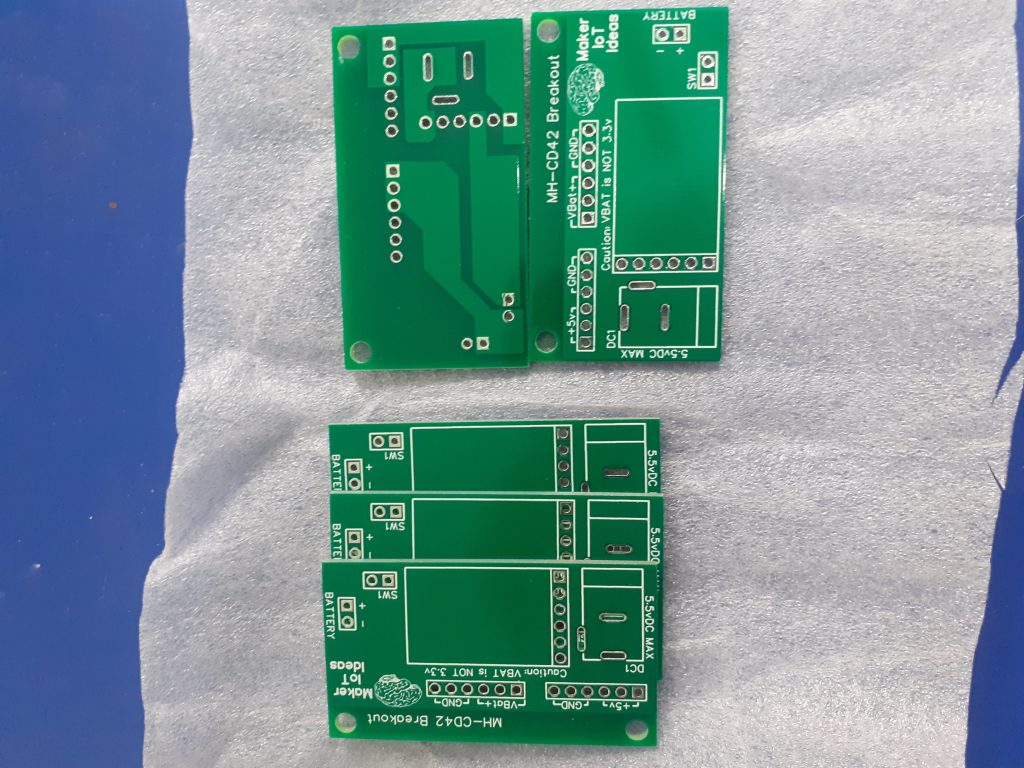

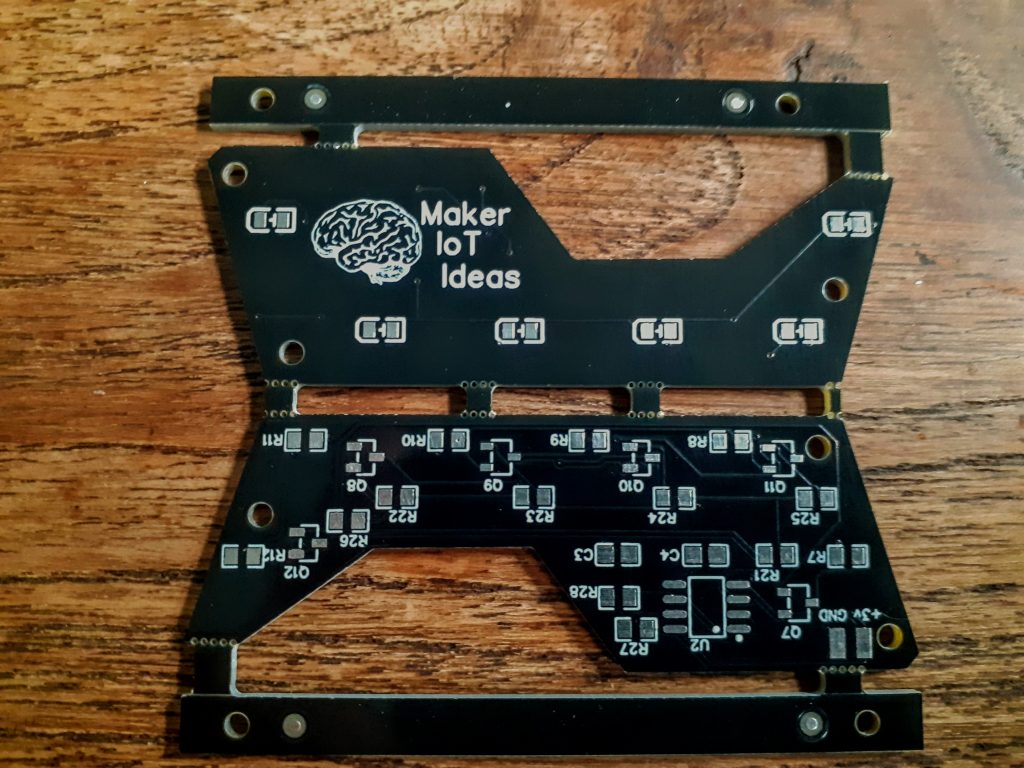

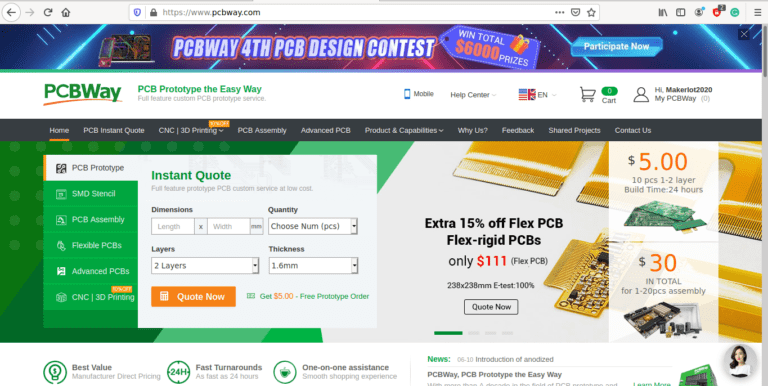

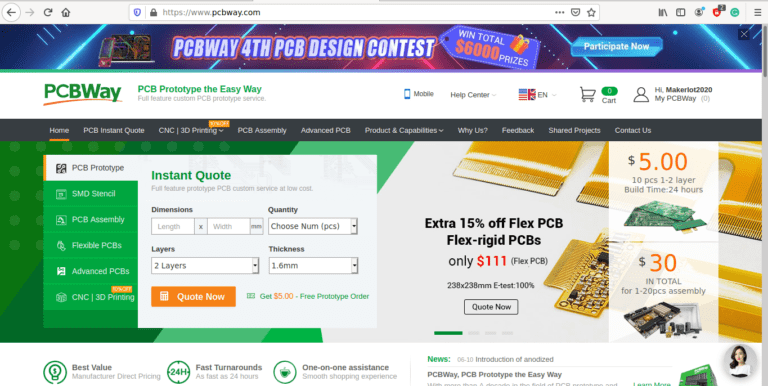

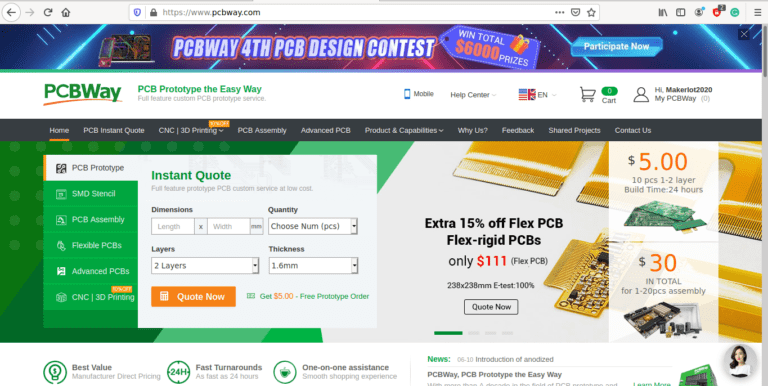

Manufacturing the PCB

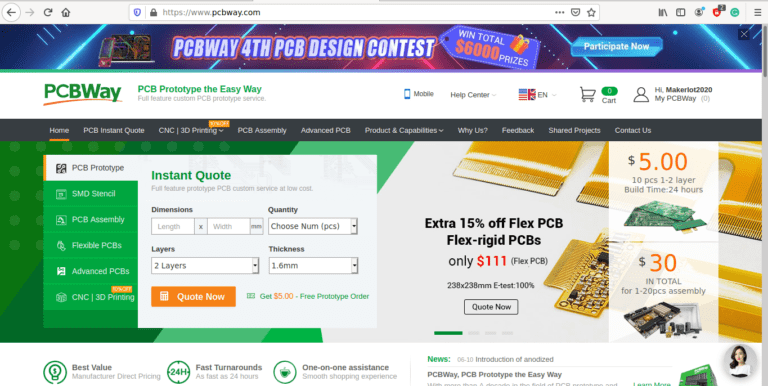

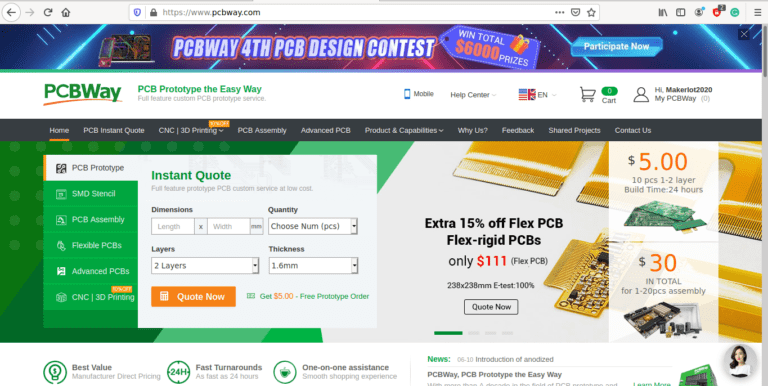

Over the past eight years, PCBWay has continuously upgraded their MANUFACTURING plants and equipment to meet higher quality requirements, and now THEY also provide OEM services to build your products from ideas to mass production and access to the market.

The PCB for this project has been manufactured at PCBWay.

Please consider supporting them if you would like your own copy of this PCB, or if you have any PCB of your own that you need to have manufactured.

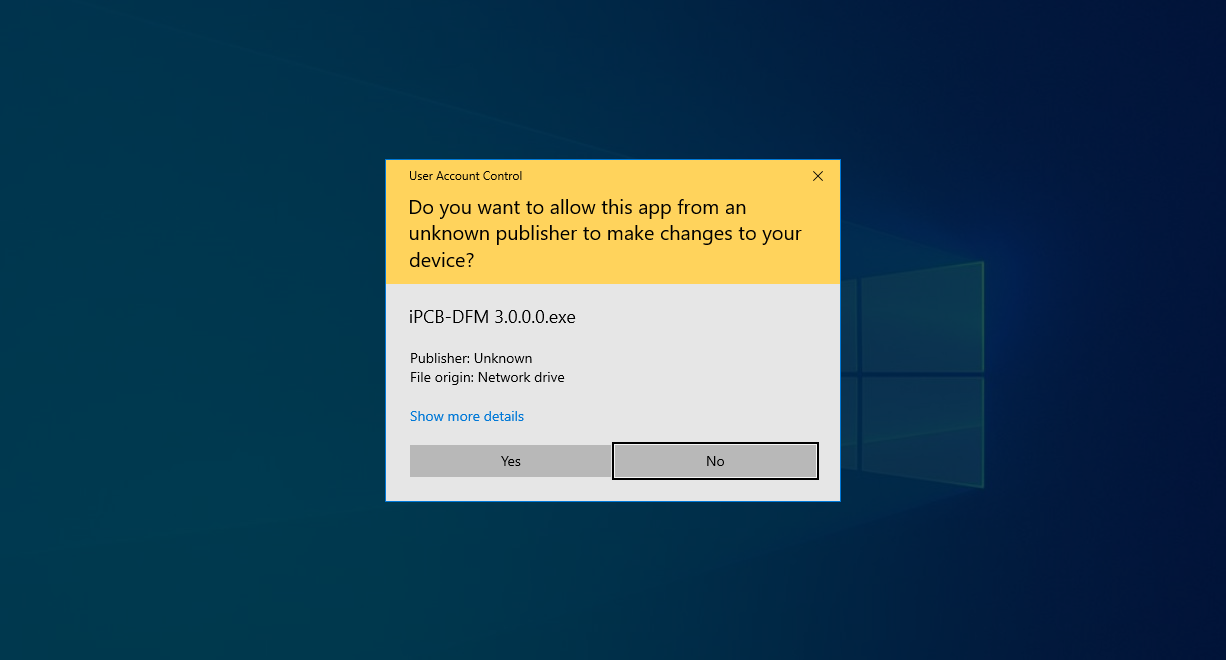

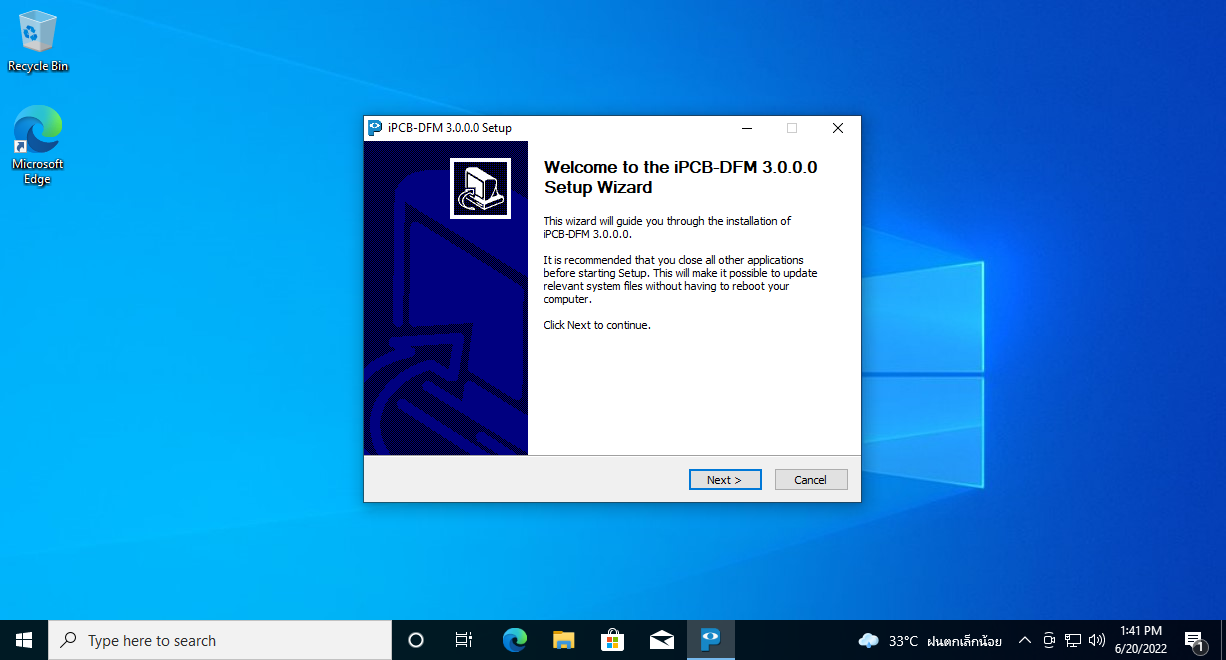

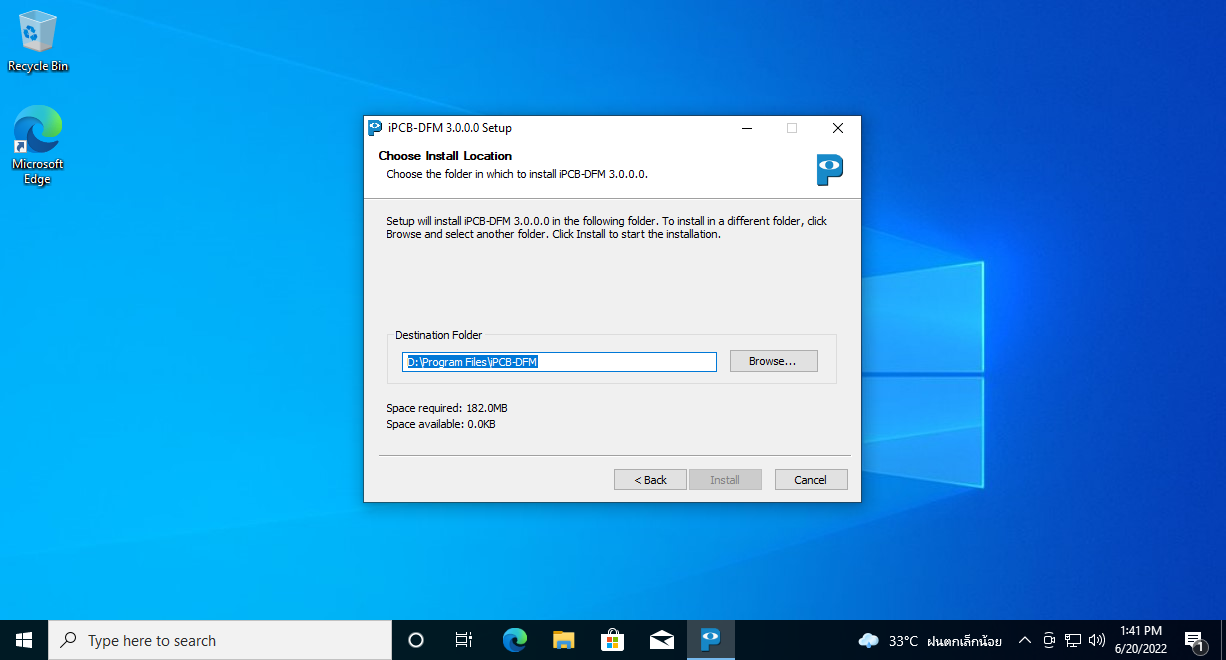

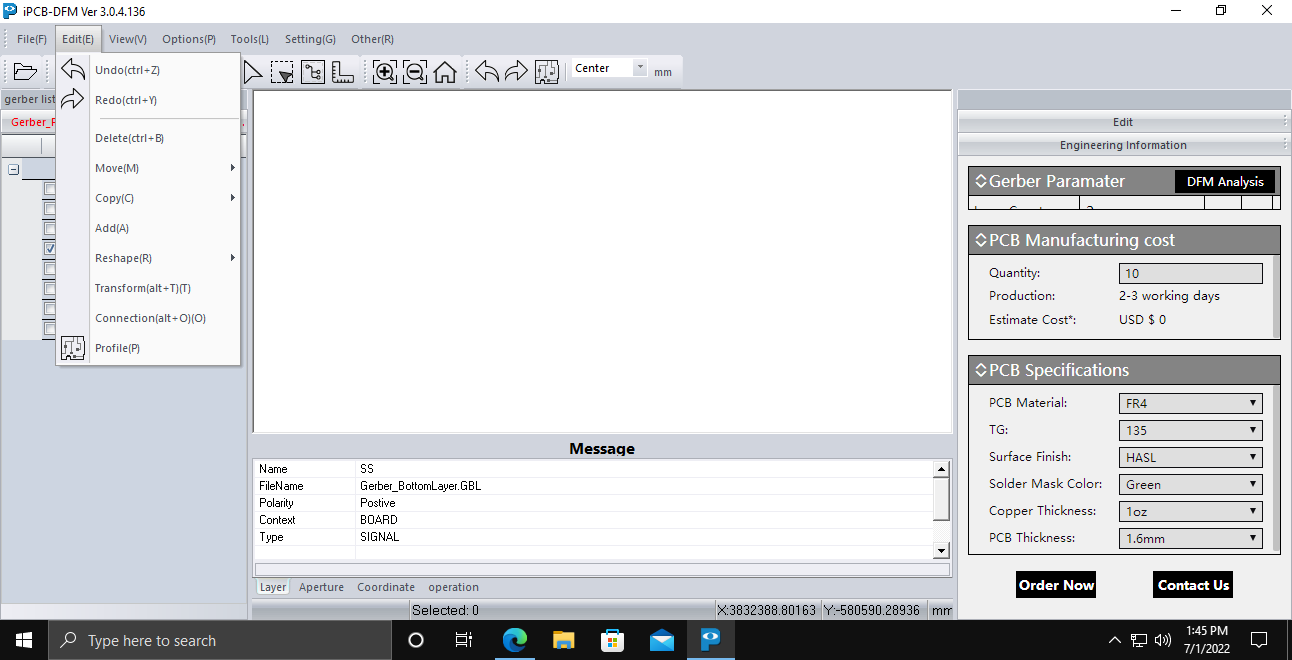

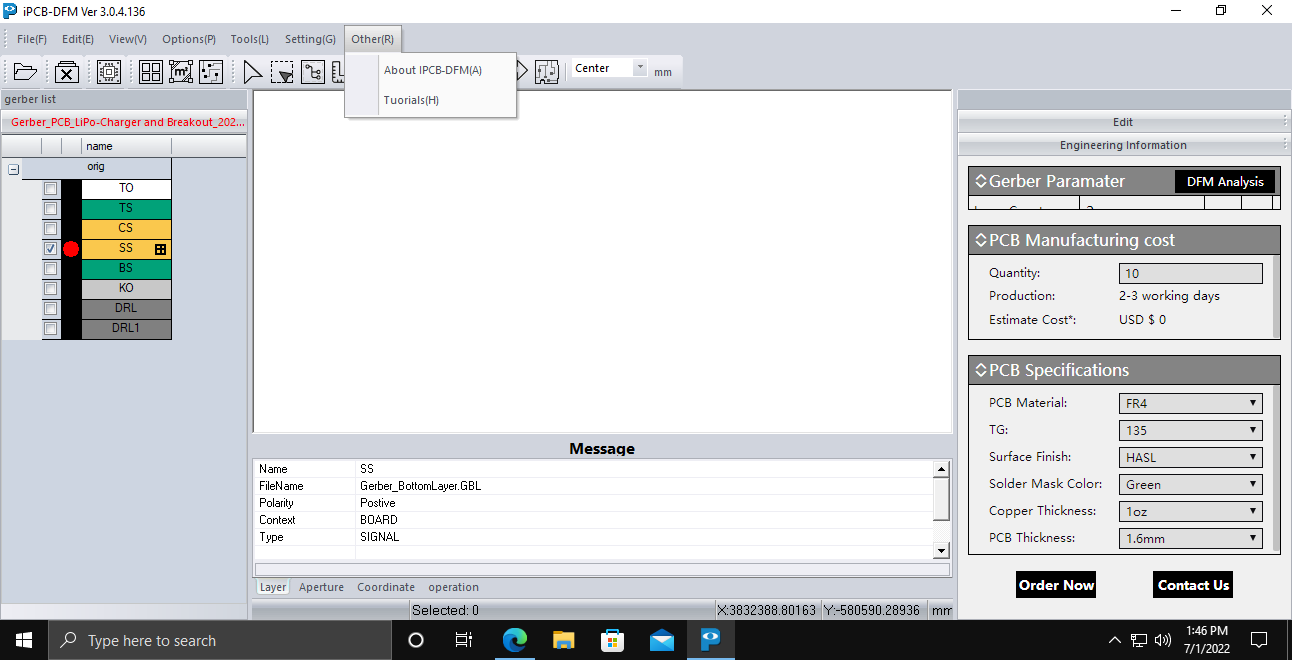

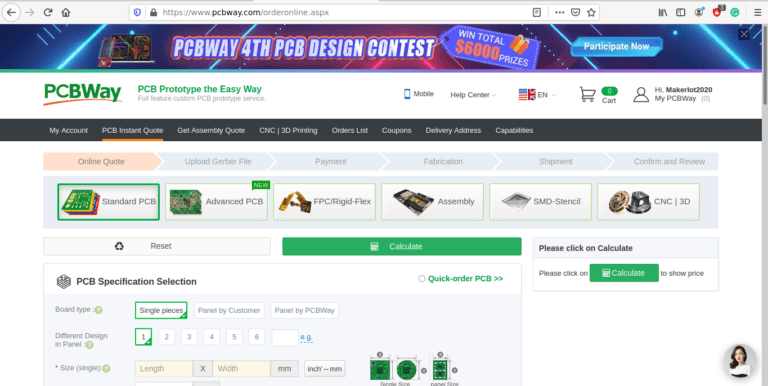

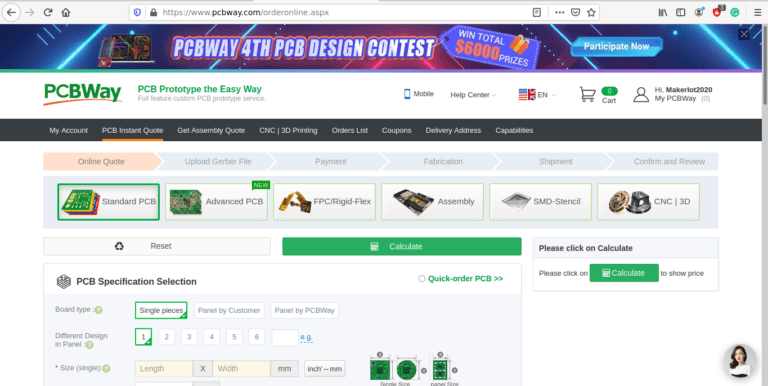

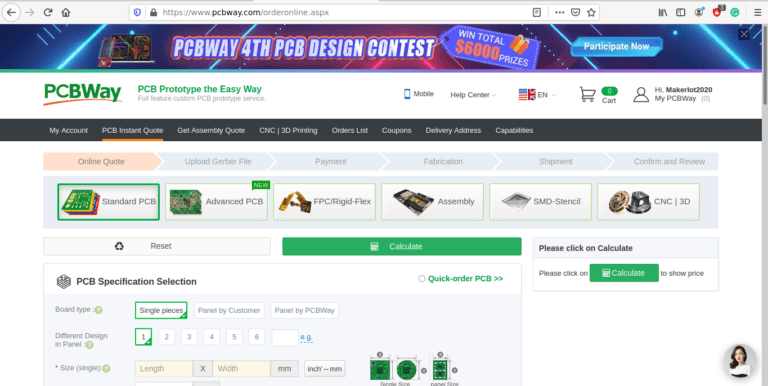

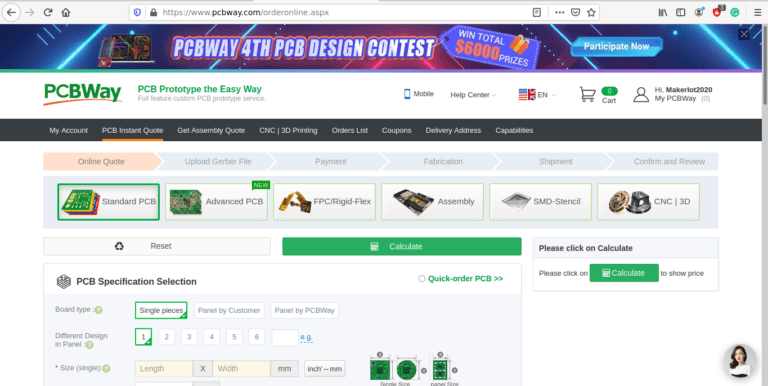

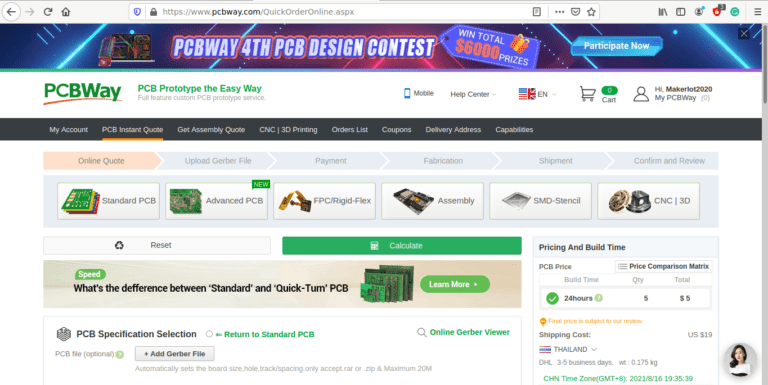

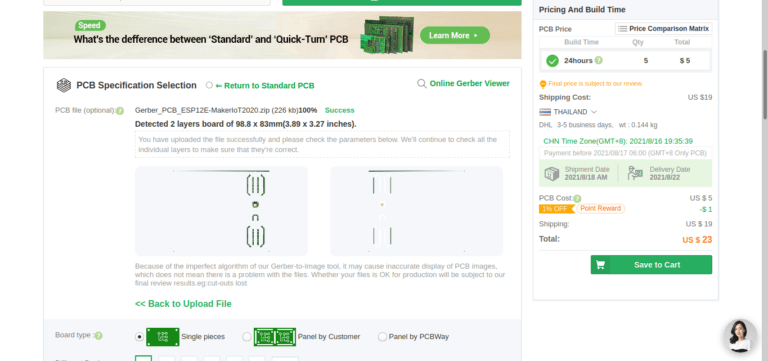

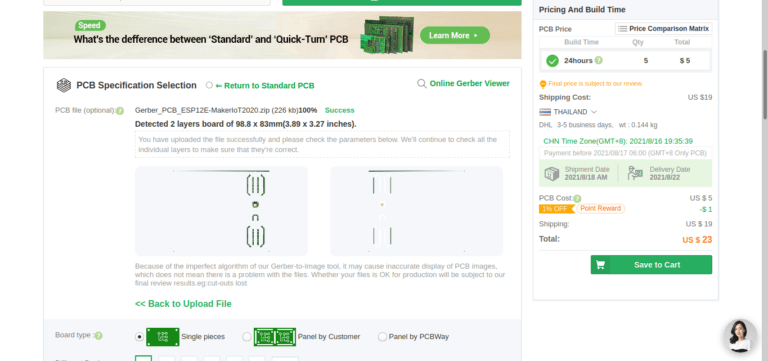

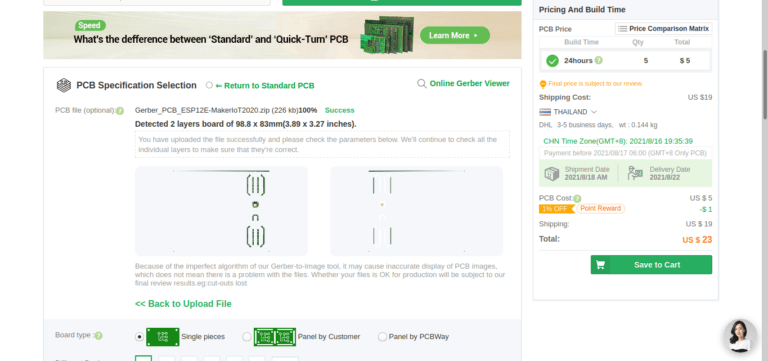

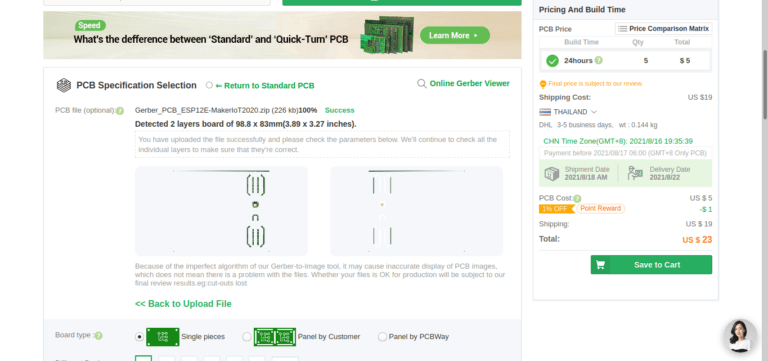

If you would like to have PCBWAY manufacture one of your own, designs, or even this particular PCB, you need to do the following…

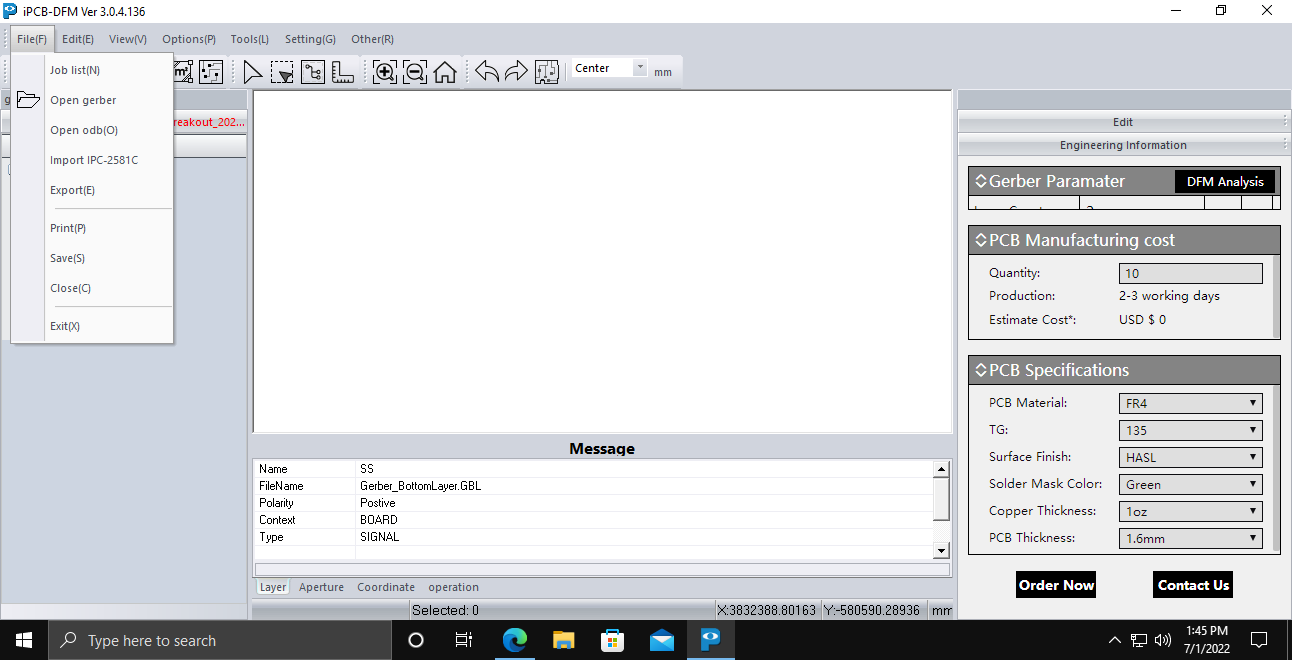

1) Click on this link

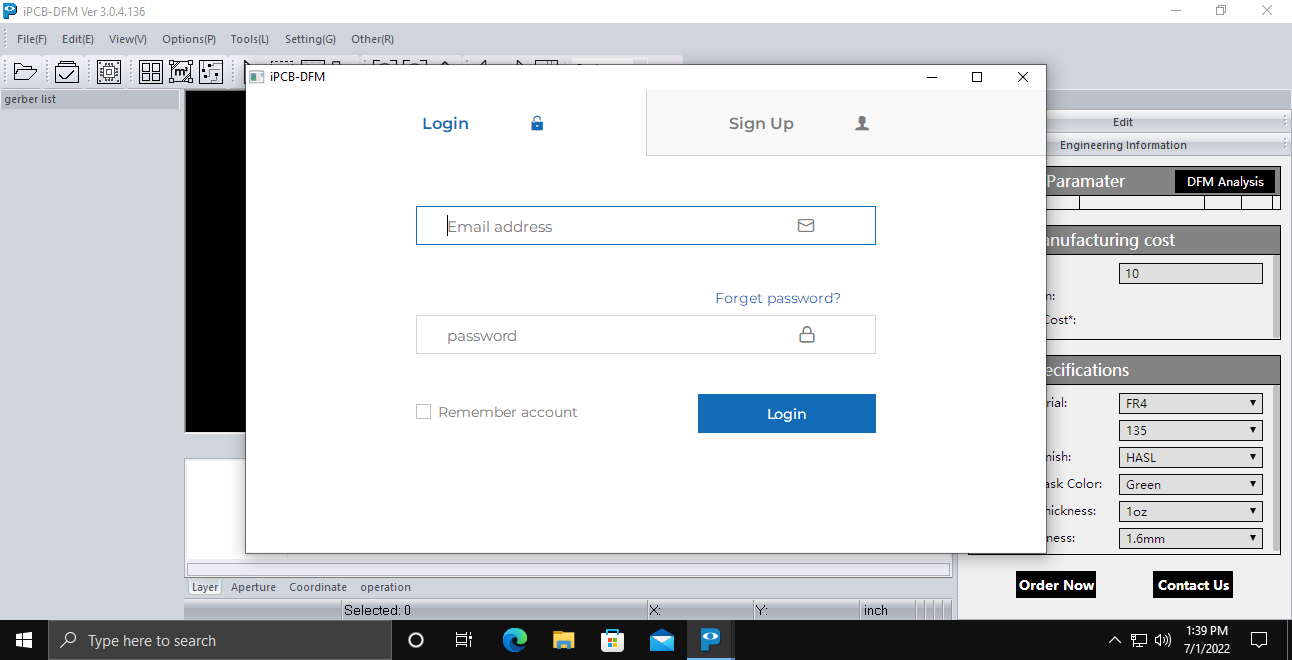

2) Create an account if you have not already got one of your own.

If you use the link above, you will also instantly receive a $5 USD coupon, which you can use on your first or any other order later. (Disclaimer: I will earn a small referral fee from PCBWay. This referral fee will not affect the cost of your order, nor will you pay any part thereof.)

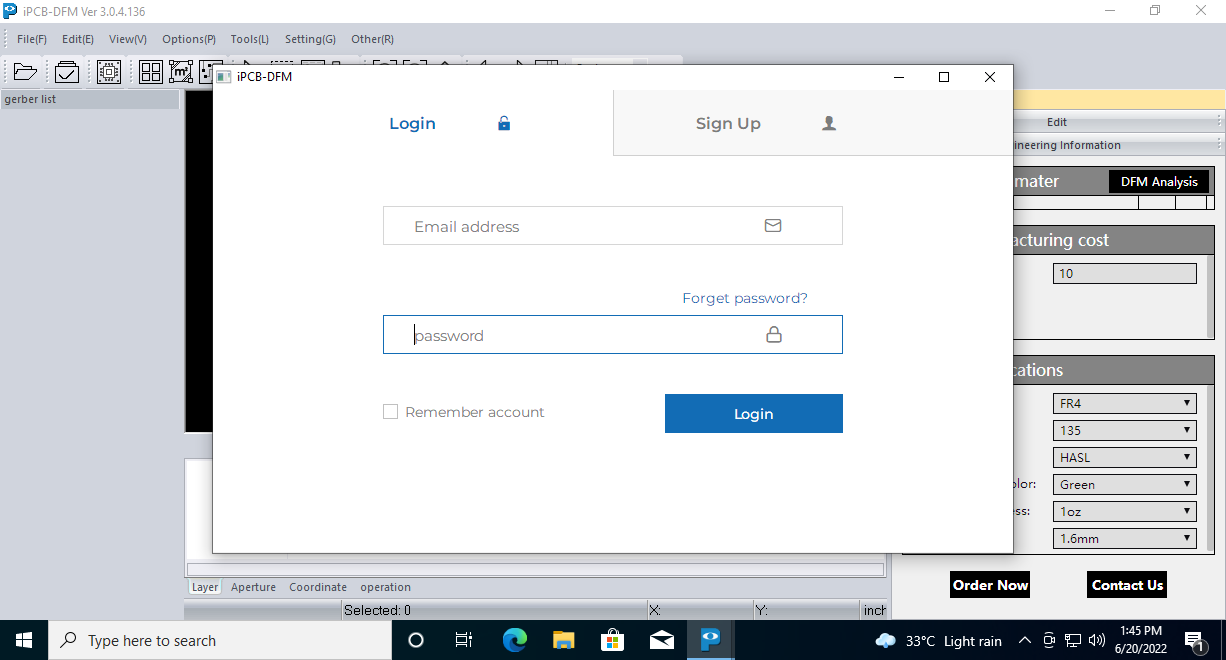

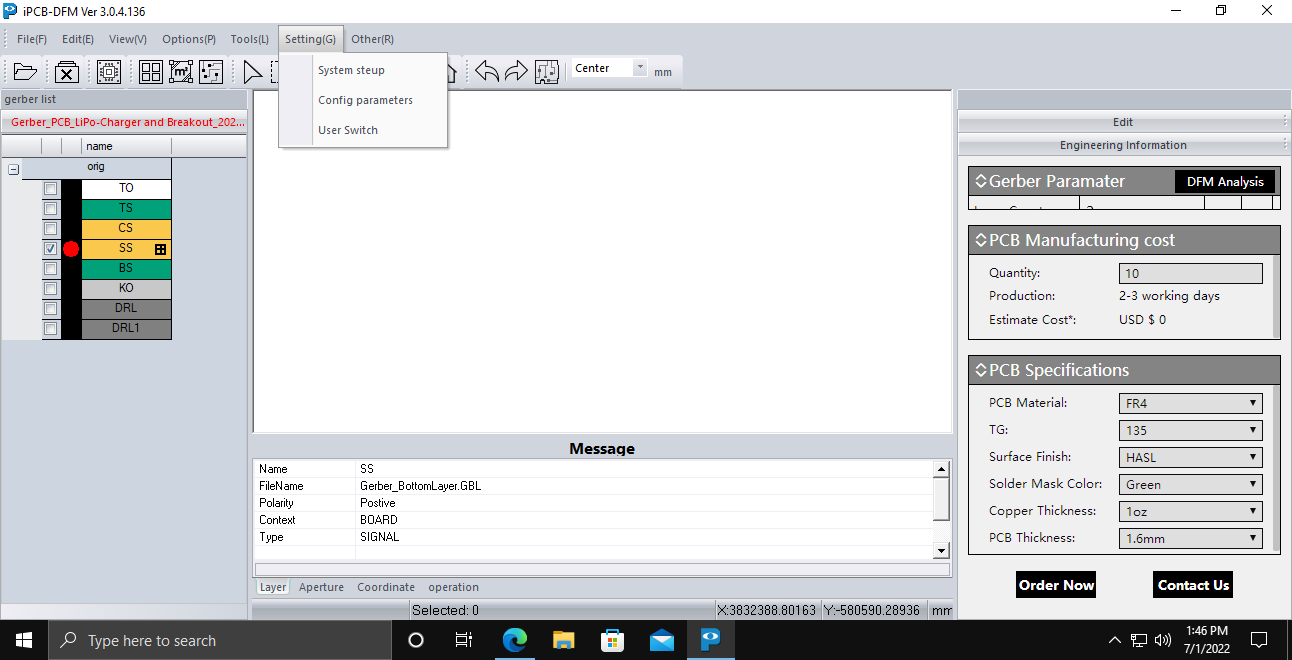

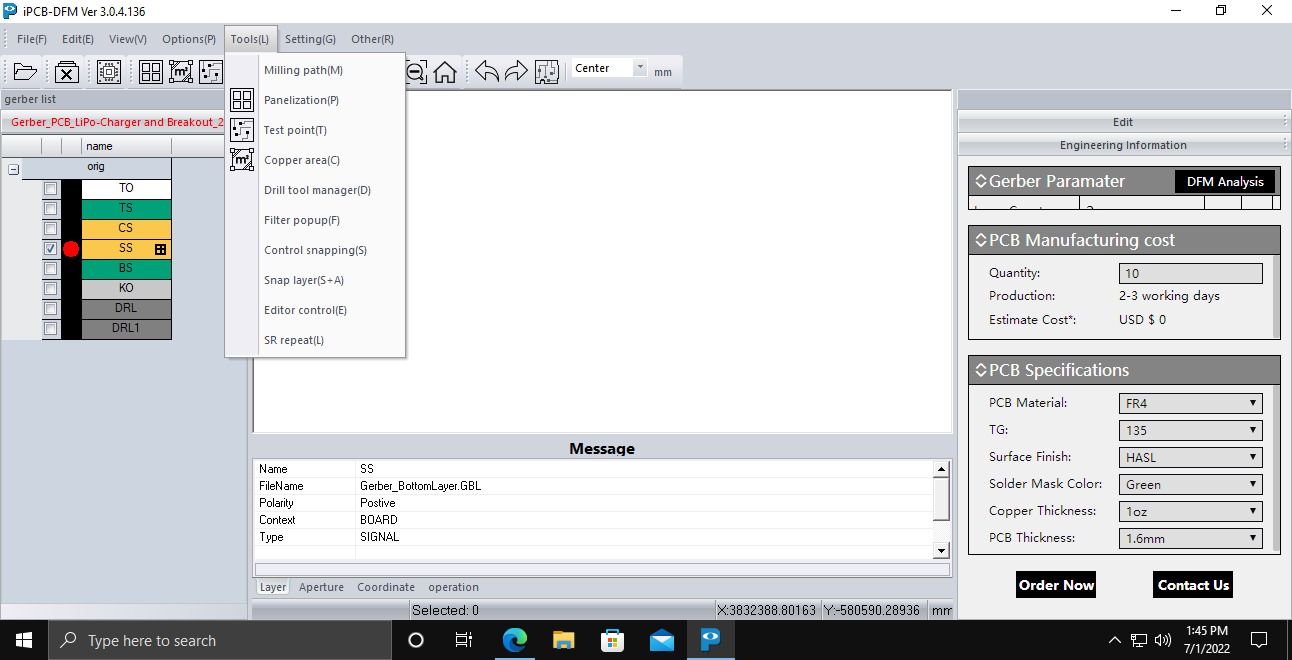

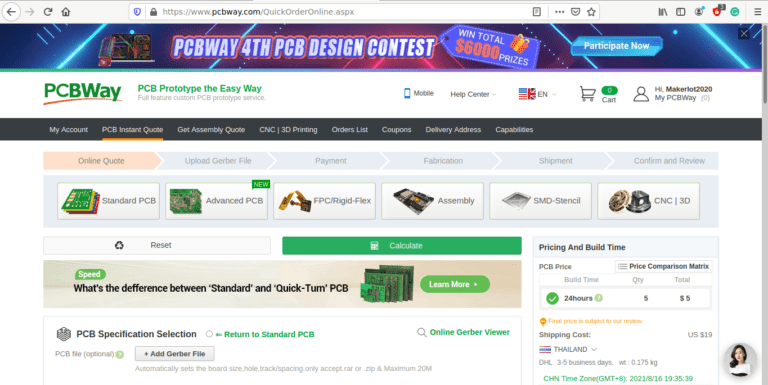

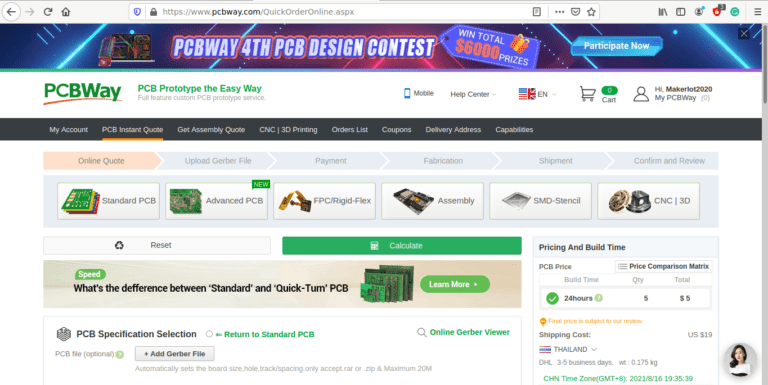

3) Once you have gone to their website, and created an account, or login with your existing account,

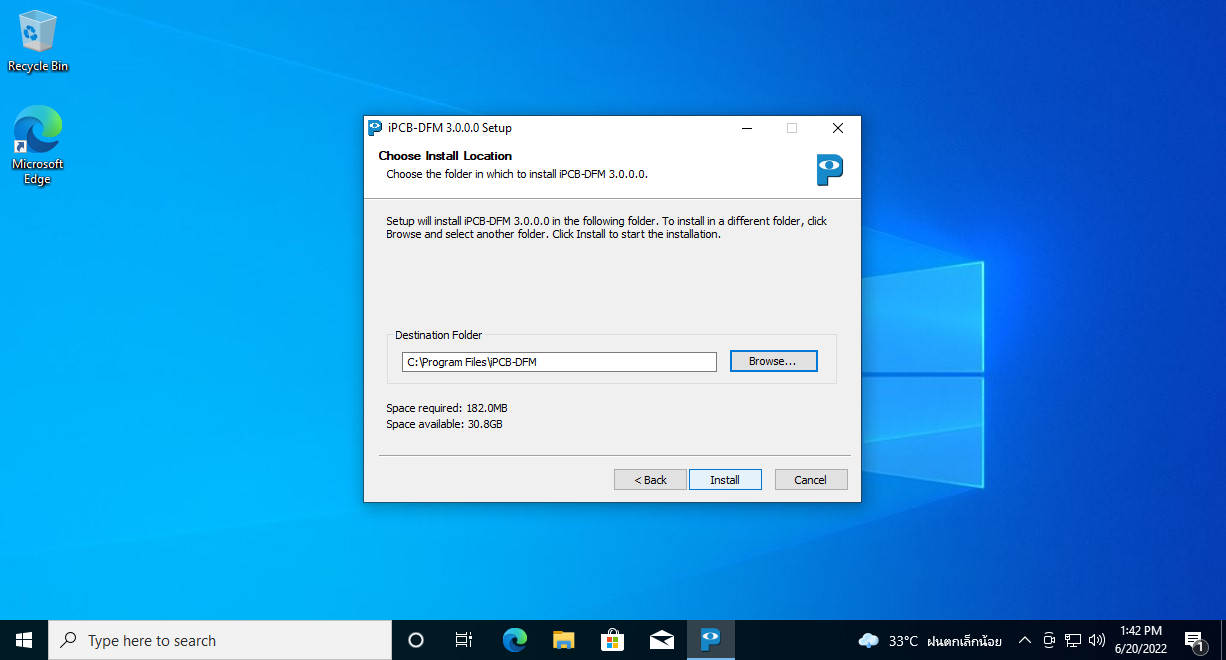

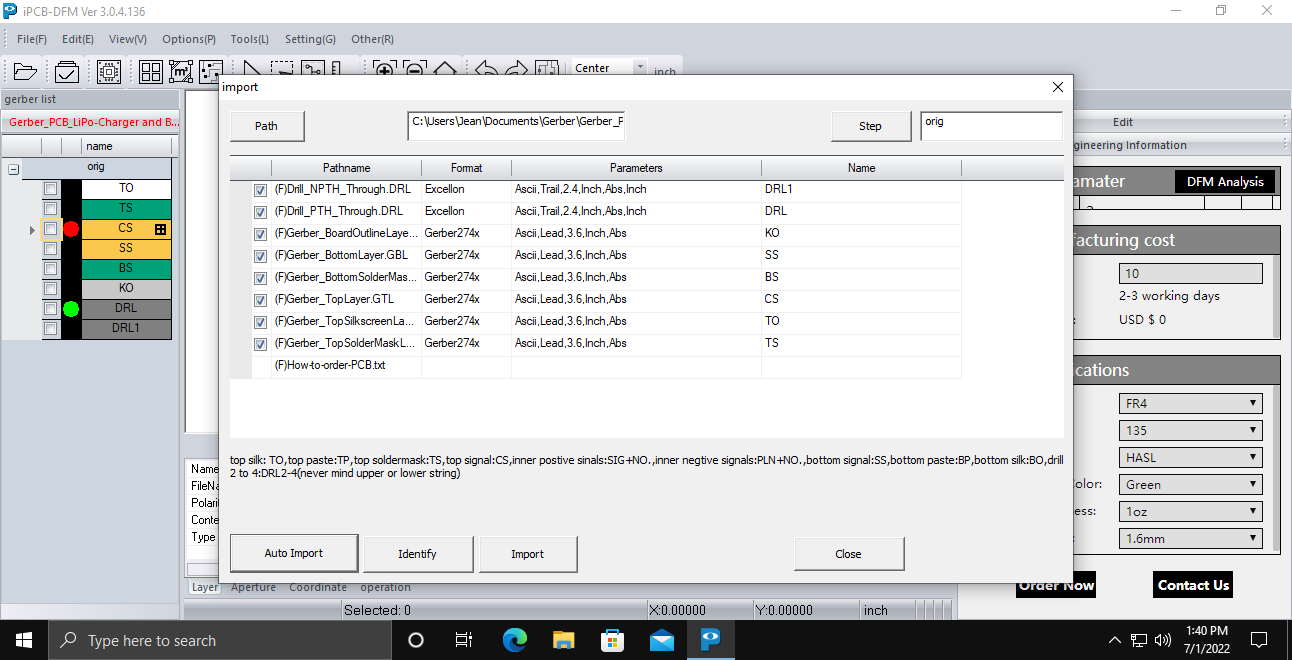

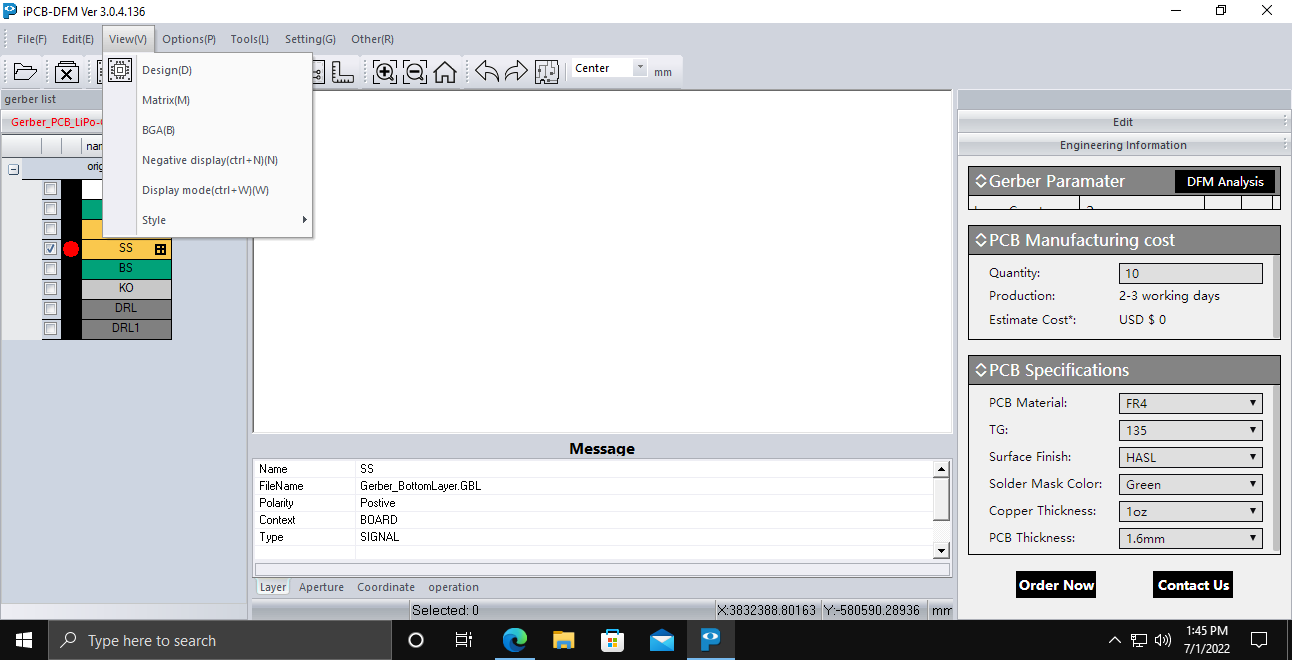

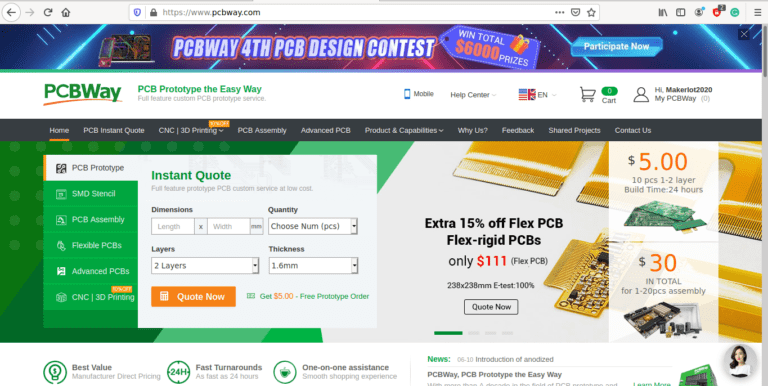

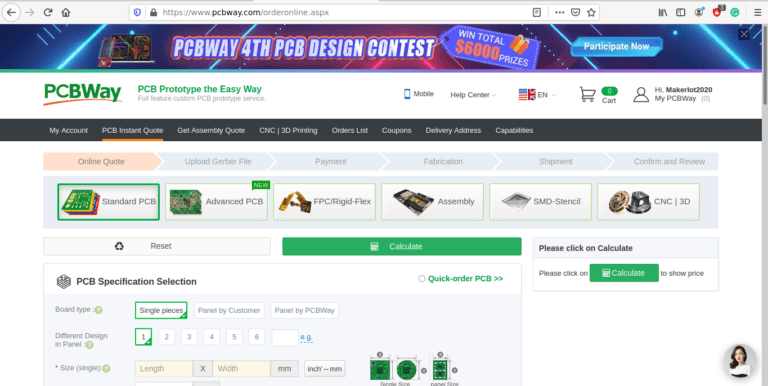

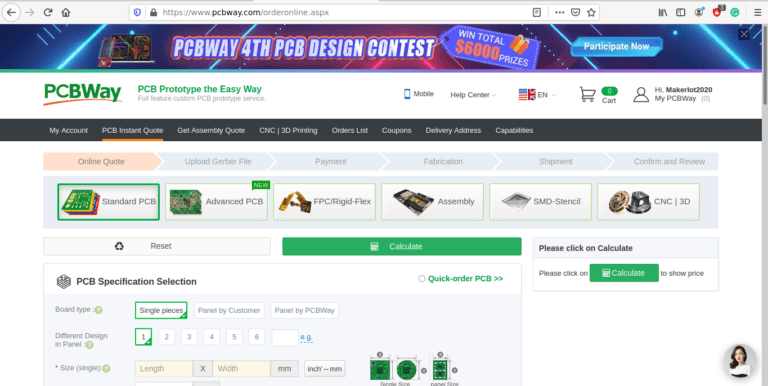

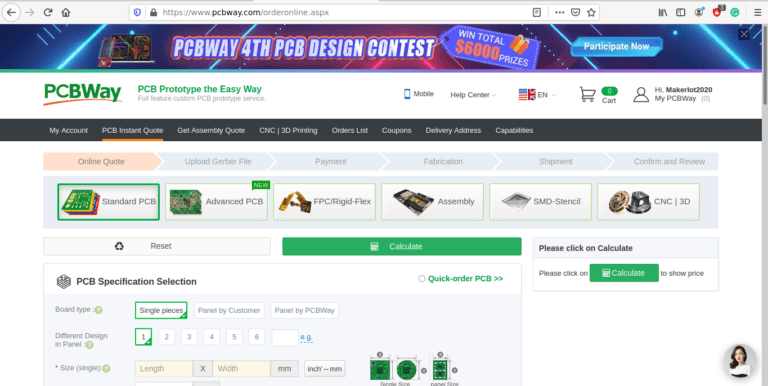

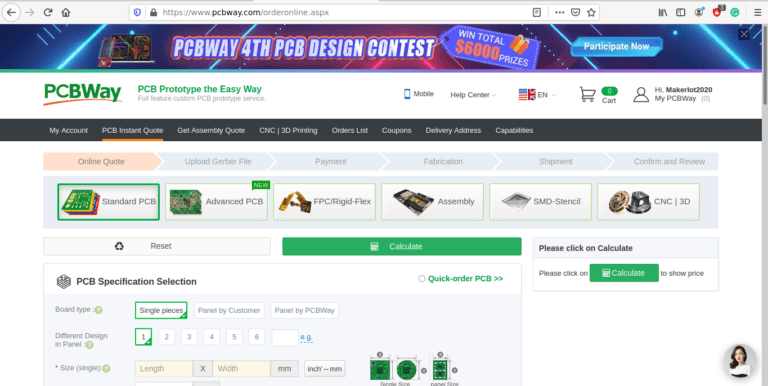

4) Click on PCB Instant Quote

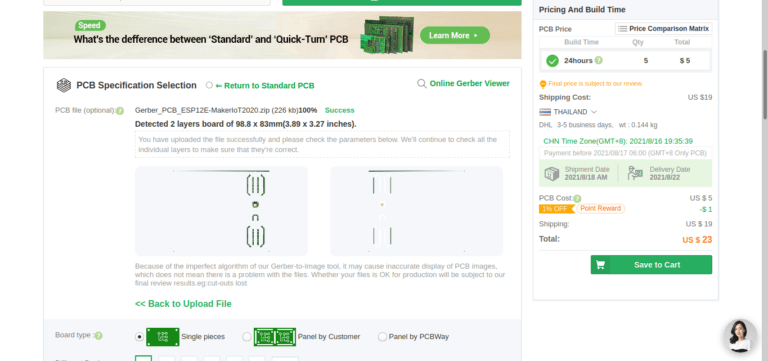

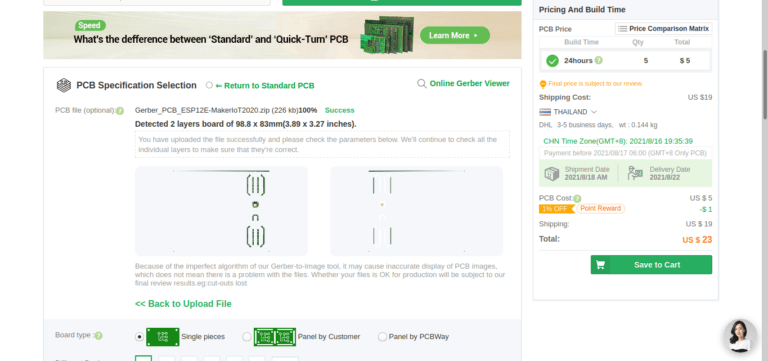

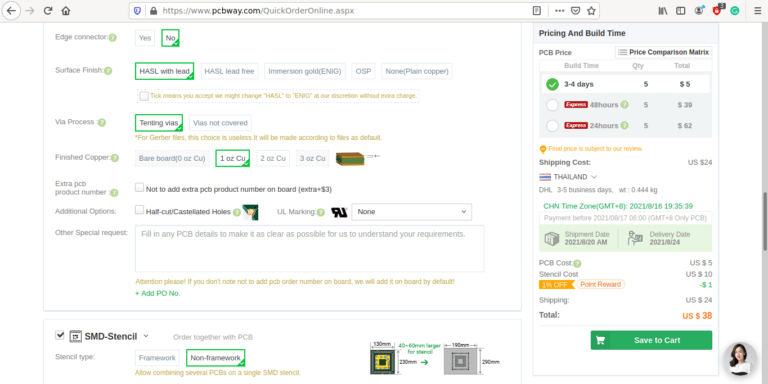

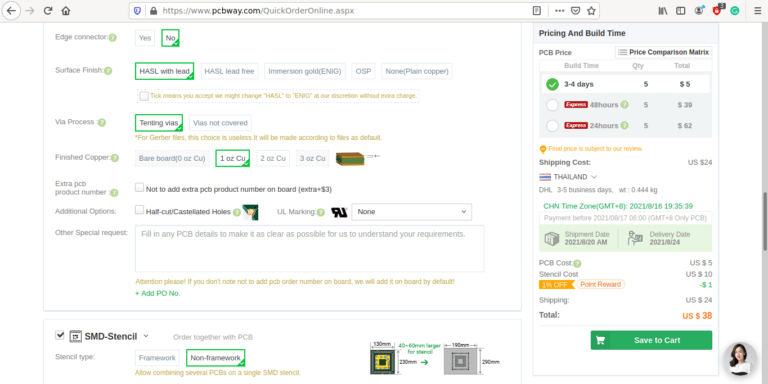

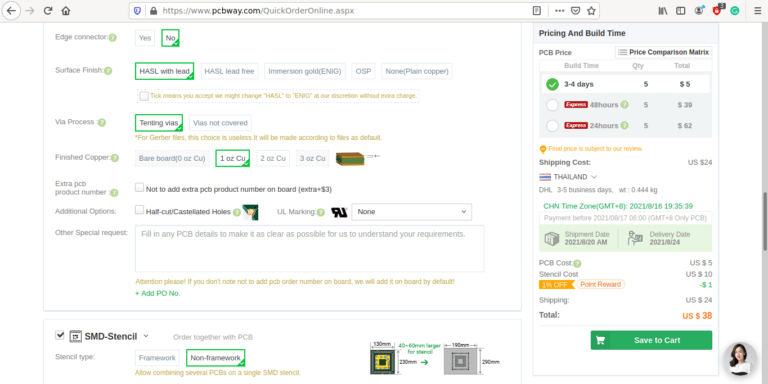

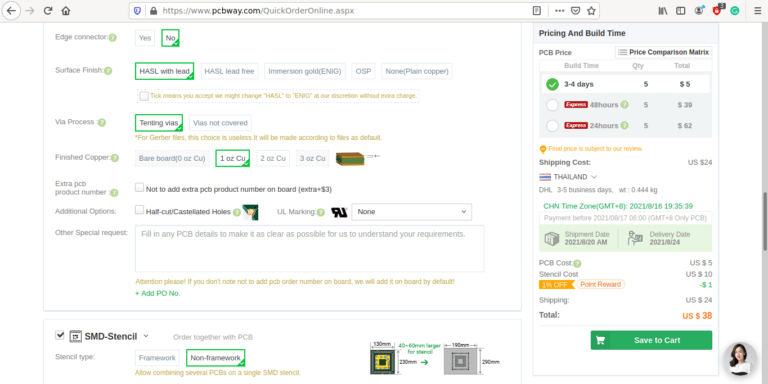

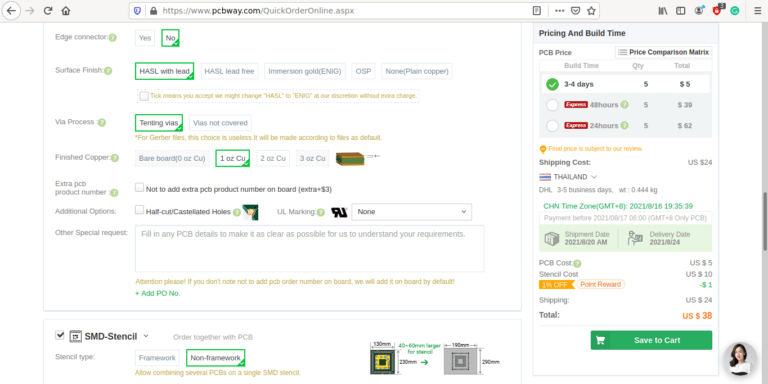

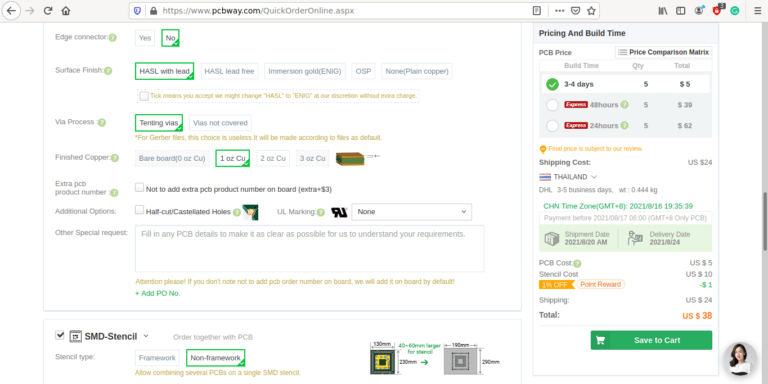

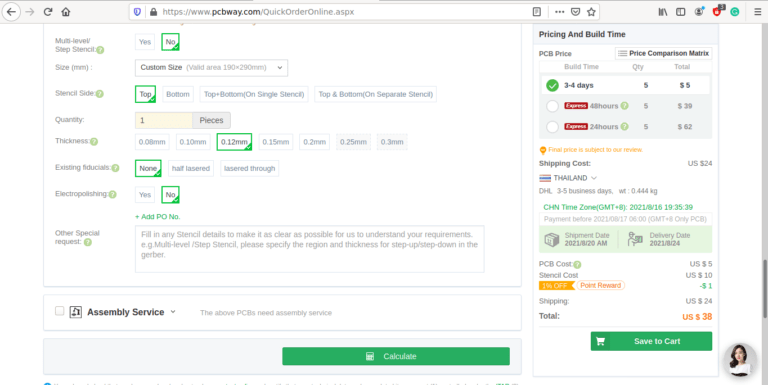

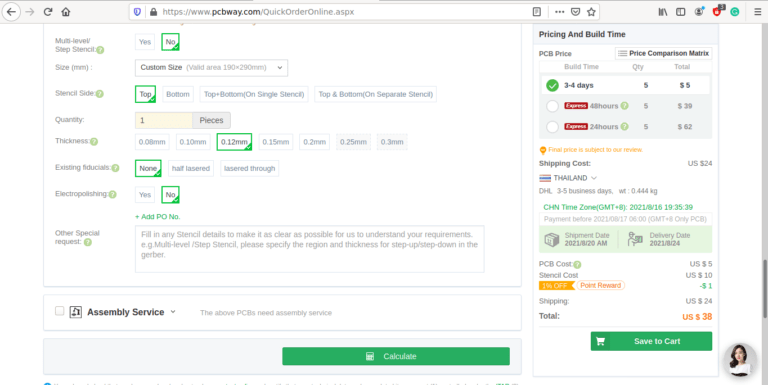

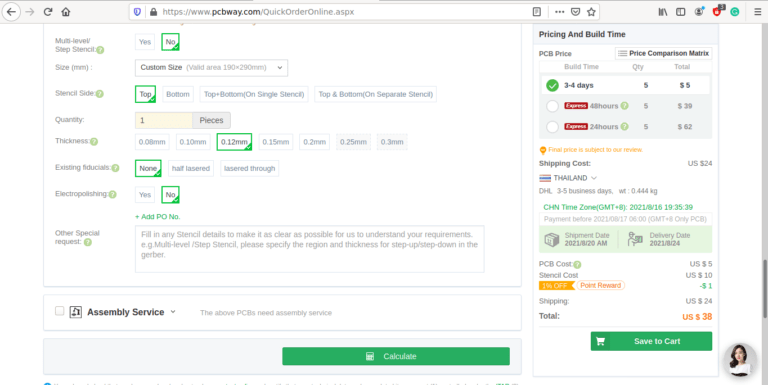

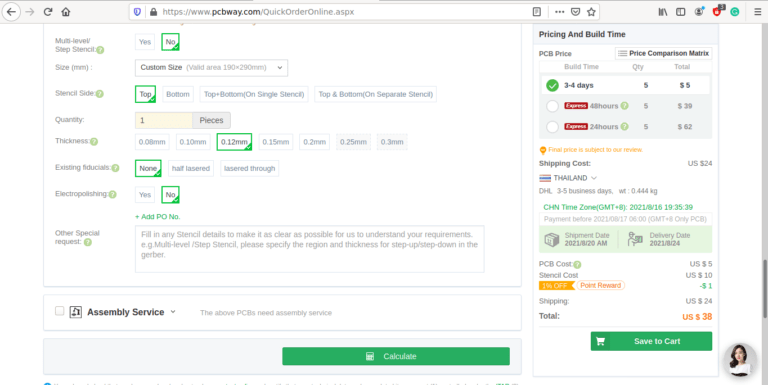

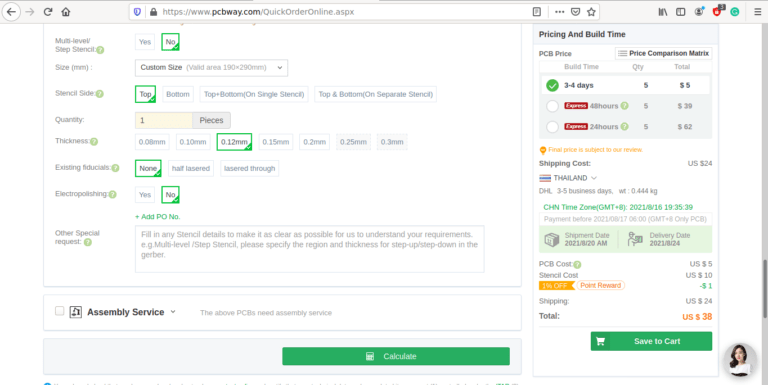

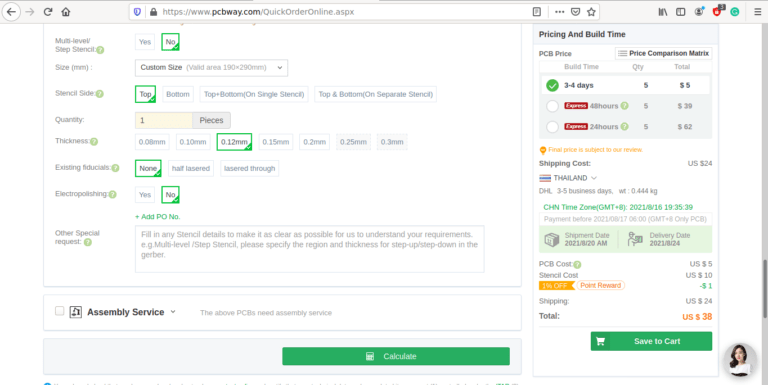

5) If you do not have any very special requirements for your PCB, click on Quick-order PCB

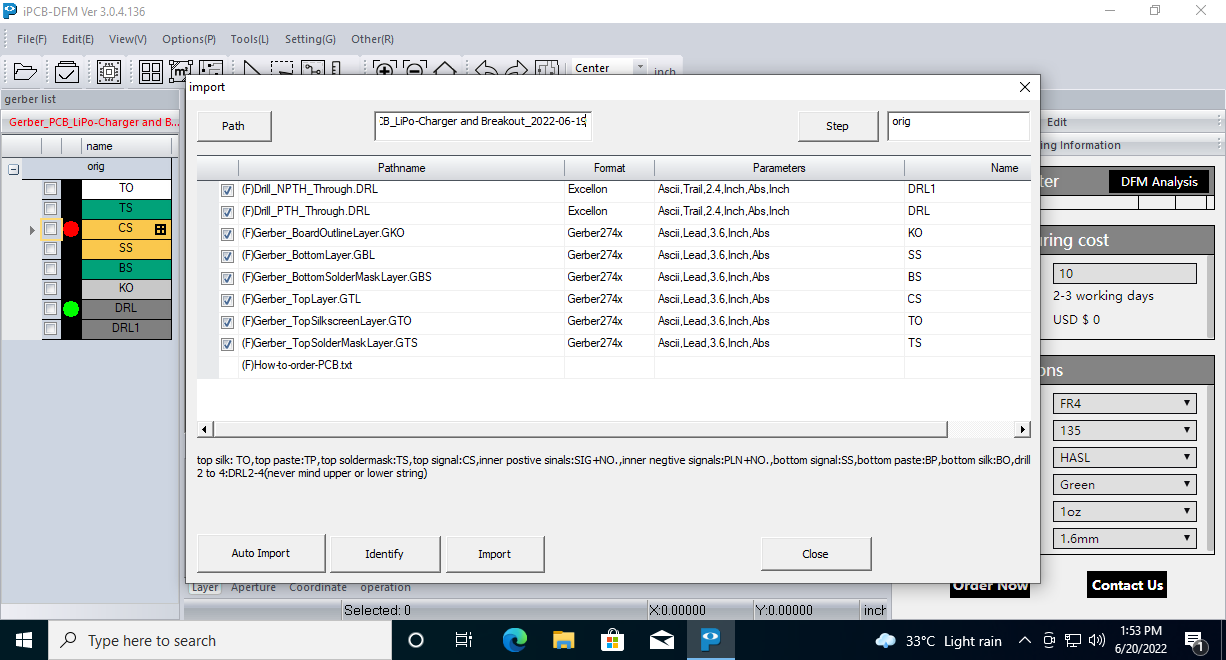

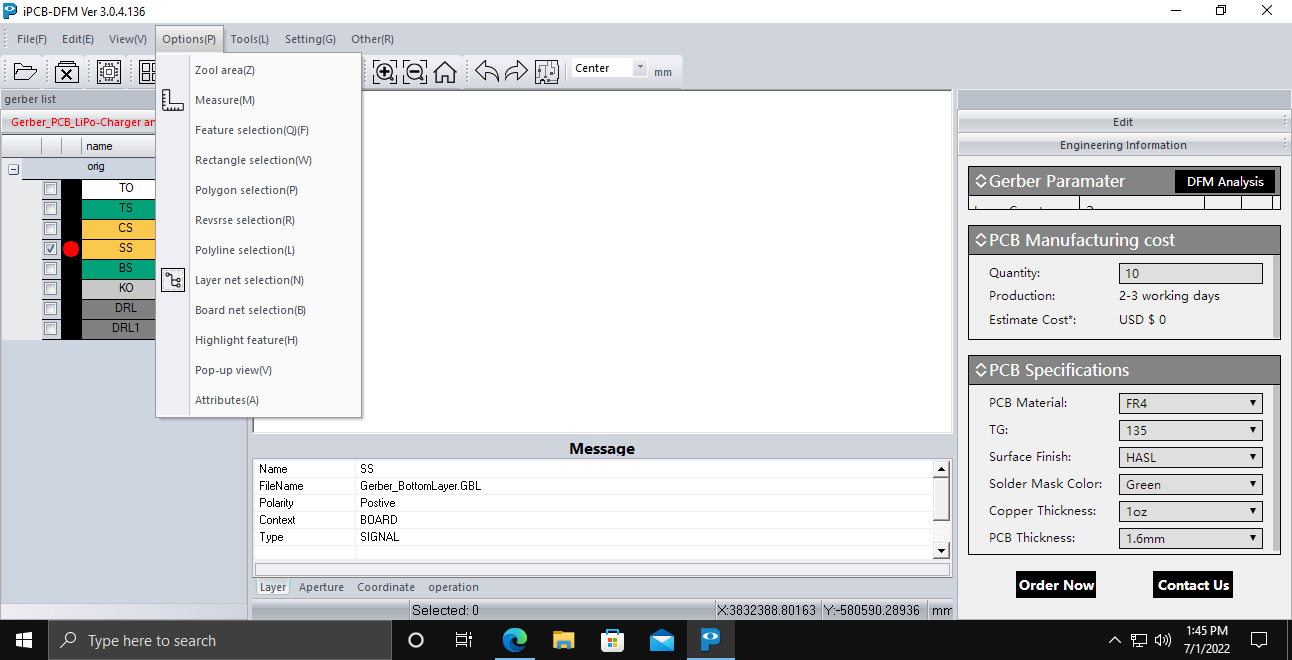

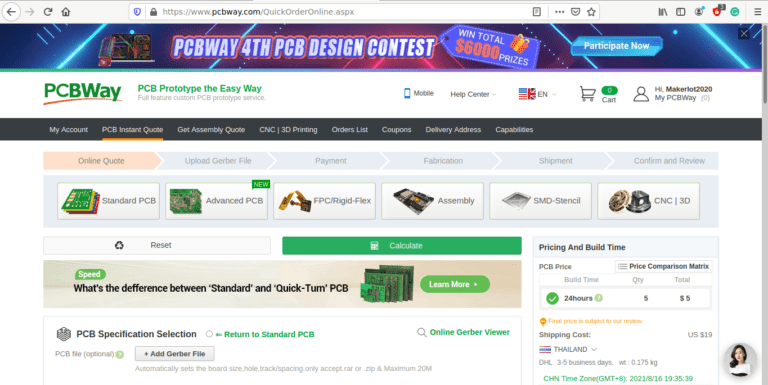

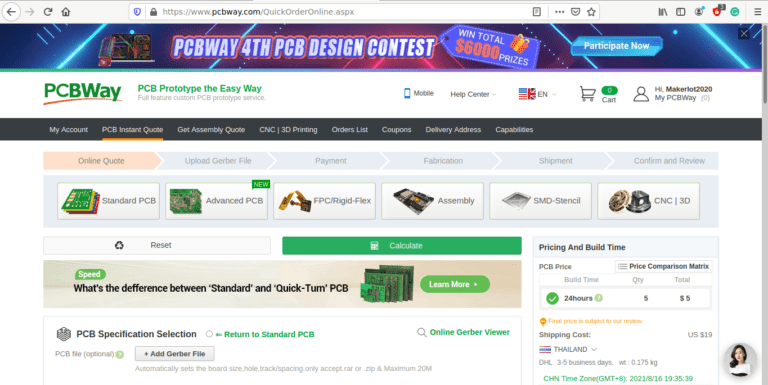

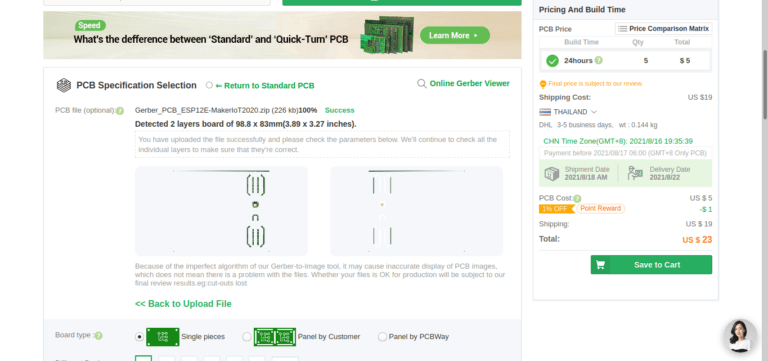

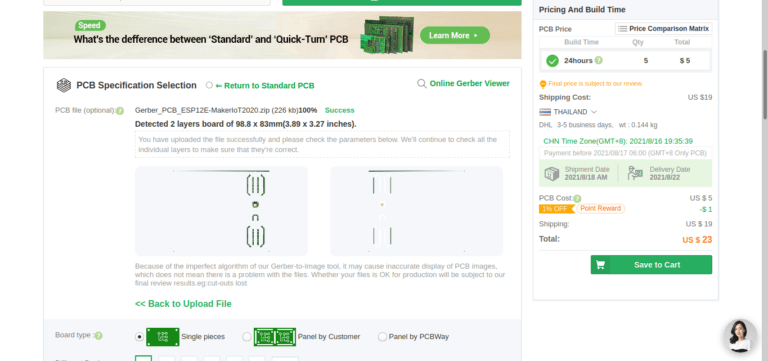

6) Click on Add Gerber File, and select your Gerber file(s) from your computer. Most of your PCB details will now be automatically selected, leaving you to only select the solder mask and silk-screen colour, as well as to remove the order number or not. You can of course fine-tune everything exactly as you want as well.

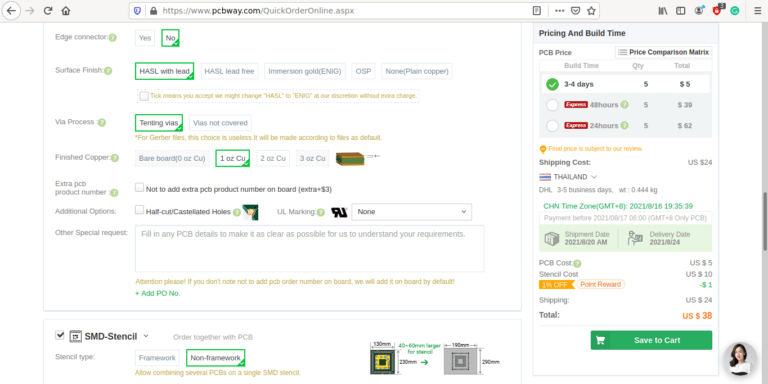

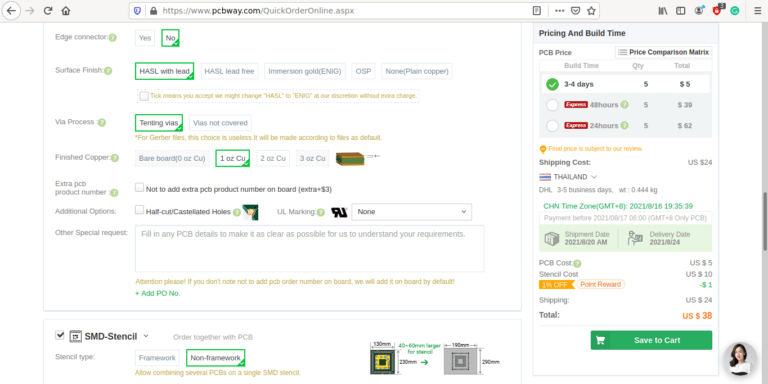

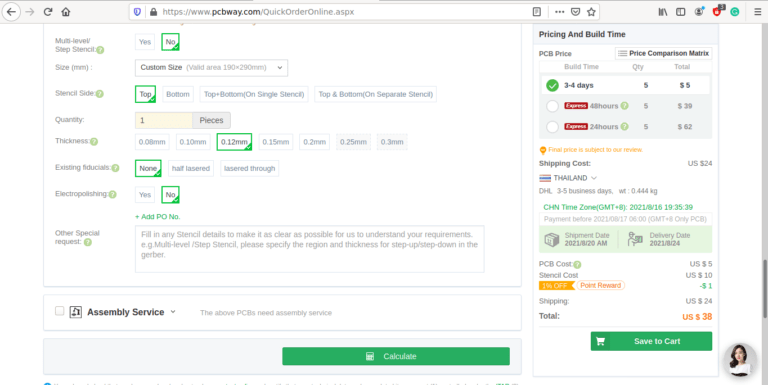

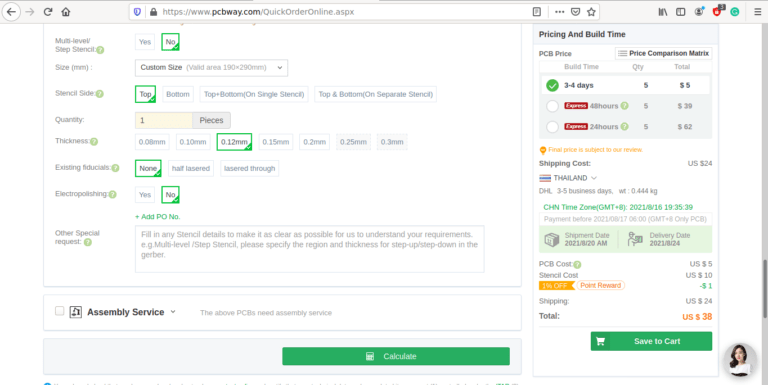

7) You can also select whether you want an SMD stencil, or have the board assembled after manufacturing. Please note that the assembly service, as well as the cost of your components, ARE NOT included in the initial quoted price. ( The quote will update depending on what options you select ).

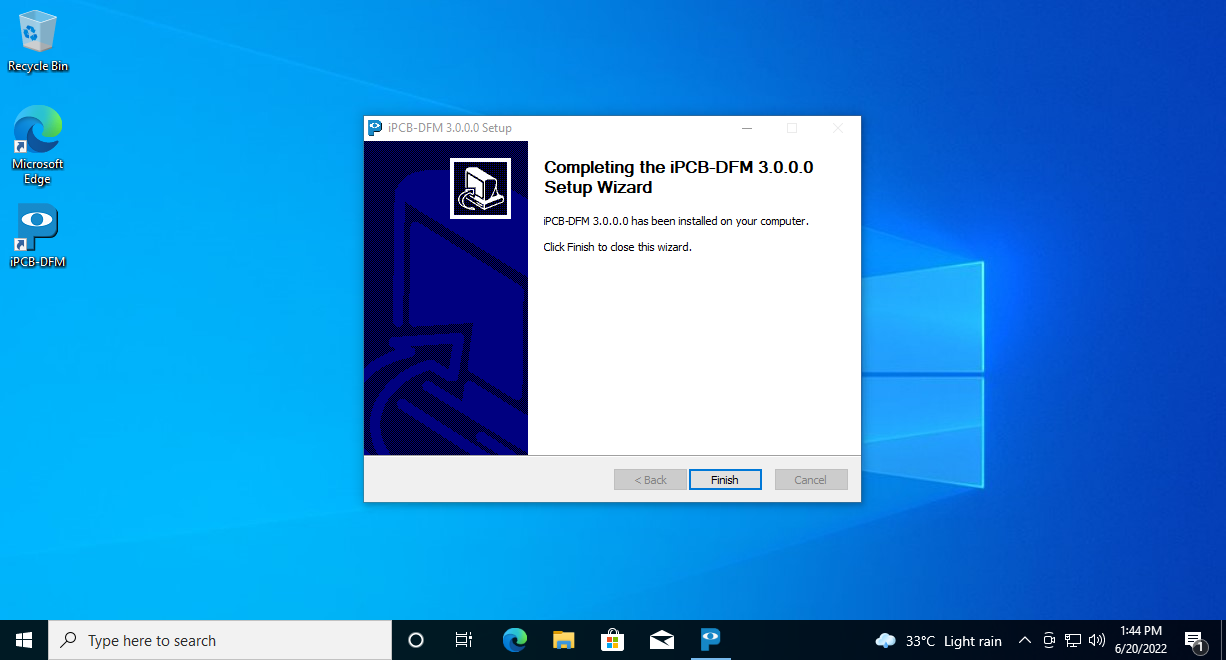

8) When you are happy with the options that you have selected, you can click on the Save to Cart Button. From here on, you can go to the top of the screen, click on Cart, make any payment(s) or use any coupons that you have in your account.

Then just sit back and wait for your new PCB to be delivered to your door via the shipping company that you have selected during checkout.